When it comes to process safety for protecting people, the environment and assets, only the best equipment will do. This is particularly true for gas measurement in industrial processes. Faced with a wide range of measurement options, users must carefully select the right technology for each measurement task. Latest developments in the field of Tunable Diode Lasers make this technology particularly attractive for achieving efficient and reliable measurement of single gas species.

Extractive oxygen measurement systems often play a major role in keeping manufacturing processes safe and maintaining inert conditions in any given situation. As a result, they must stand up to the toughest conditions and as a consequence, significant maintenance is required to keep their performance at an acceptable level.

Typically, the total lifetime maintenance costs for an extractive oxygen analyzer with sampling and conditioning system can add up to twice the purchasing, engineering and installation costs incurred during the initial phase. This not only burdens maintenance budgets, it also jeopardizes the overall process yield since paramagnetic systems can fail abruptly if moisture and dust enter the measurement cell. These significant drawbacks can be overcome by using Tunable Diode Lasers (TDL) that are able to measure in situ, with high accuracy and reliability, and with virtually no maintenance.

Laser technology for interference-free analysis

Oxygen analyzers that are able to provide faster measurement and more accurate results are always going to be of interest to the chemical industry. If they also have a significantly lower cost of ownership compared with other systems, it adds up to a very attractive value proposition. In narrow-bandwidth laser spectroscopy, the absorption of light is measured at discrete lines using finely tuned VCSEL or DFB lasers routinely used in the communications industry. Such laser diodes can be tuned to emit a very specific wavelength that matches the part of the spectrum where single absorption lines for a particular gas species to be detected are available. By controlling the laser temperature as well as the feed current, a narrow “scan” of the selected absorption lines can be performed in order to determine the surface area of the lines and hence the concentration of the gas species.

Using absorption spectroscopy, gases frequently measured in industrial processes such as oxygen can be measured in situ, directly in the gas stream and bypassing any sampling and conditioning. This is achievable up to temperatures of 1500 °C or 10 bar and excludes any possible interference from background gases. Because absorption is attenuated due to the presence of dust in the gas stream, a reduction of signal intensity can be expected. However, most TDLs on the market are able to cope with 90 % attenuated signals.

Simplified installation and commissioning

This technology has been known for over two decades, and throughout this period has continuously been refined to improve performance and drive down costs. However, users of TDLs must also be aware of the effort and care needed in order to make these analyzers perform the way they should, right from day one. Areas where users have frequently reported difficulties are:

Selection of the measurement point for temperature and pressure inputs:

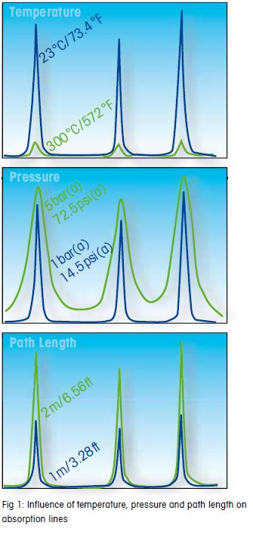

- Absorption lines change shape with temperature and pressure (see Fig. 1), so in order to calculate a correct concentration value, temperature and pressure of the gas stream must be measured. This is usually done by external sensors mounted in the pipe. If the value provided by the sensors is not representative of the gas to be measured, a considerable error results. As a rule of thumb, a 50 mbar deviation results in a 1 % deviation of the air concentration value.

- Selection of the right purging speed: TDL is a non-contacting measurement method; therefore, the laser diode and detector must be separated from the process by windows. In a typical cross-stack TDL setup, separate purging lines for the sender and the receiver unit on both sides of the stack must be pulled. The purge gas, usually nitrogen, flushes the windows process side to keep them free of detrimental dust sedimentation that could rapidly decrease signal intensity. What is more, the purging speed needs to be carefully selected, as a build-up of nitrogen shortens the measuring distance of the laser and results in measurement error.

- Alignment of flanges for sender and receiver units: Although the laser beam is by no means as collimated (parallel) as a laser pointer for presentations, both units need to be aligned within 1 – 2 ° for the beam to hit the detector. So flanges must be welded on both sides of the pipe with high accuracy for basic alignment, and the fine adjustment is then done by positioning screws on the sender or receiver unit. It is not uncommon that this alignment procedure needs to be repeated when the hot process is running, to account for different thermal expansions on both sides of the pipe or conduit.

In-situ TDL in probe design

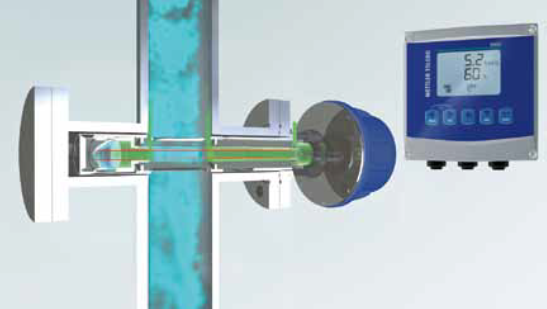

Cross-stack design for in-situ TDLs is frequent, but not the rule. A valid option to overcome some of the installation hazards are probe-style TDLs. A probe is a part of the sensor that protrudes into the process gas stream. In a probe TDL, the laser diode and the detector sit on the same side of the pipe. The outgoing beam is reflected back to the detector using a corner cube (see Fig. 2 below). A corner cube has the ability to reflect back the laser beam parallel to the outgoing beam, at any orientation of the corner cube. So the optical path is aligned by factory settings.

Fig 2: Probe-style Mettler Toledo GPro 500 TDL with folded path configuration and corner cube (left)

This TDL probe design offers significant advantages over cross stack TDLs:

- Alignment of the flanges is obsolete, since the whole optical path is geometrically set by the probe itself, offering plug-and-play installation.

- The spectrophotometer is detachable from the probe that also serves as a process interface sealing from the gas stream. So maintenance to the analyzer is possible without process interruption.

- The optical path is “folded”, which means that for the same insertion length, the beam path is doubled, thereby doubling the accuracy of the sensor. Consequently, good detection limits can be reached even in small pipe diameters, which greatly improves the ability to measure gas concentration where the process requires it, not just where the cross-stack TDL can be accommodated.

Additionally, advances in processing power have allowed TDLs to become more compact, so that purged enclosures for use in hazardous areas can be replaced by explosion-proof ones that comply with FM and ATEX regulations. This also means that for hazardous area compliance, it is no longer necessary to use long and costly fiber connections between process gas-wetted elements and the analyzer electronics. This can become a significant advantage when selecting the installation point in the process, since the footprint of probe TDLs is minimal.

Advanced signal processing

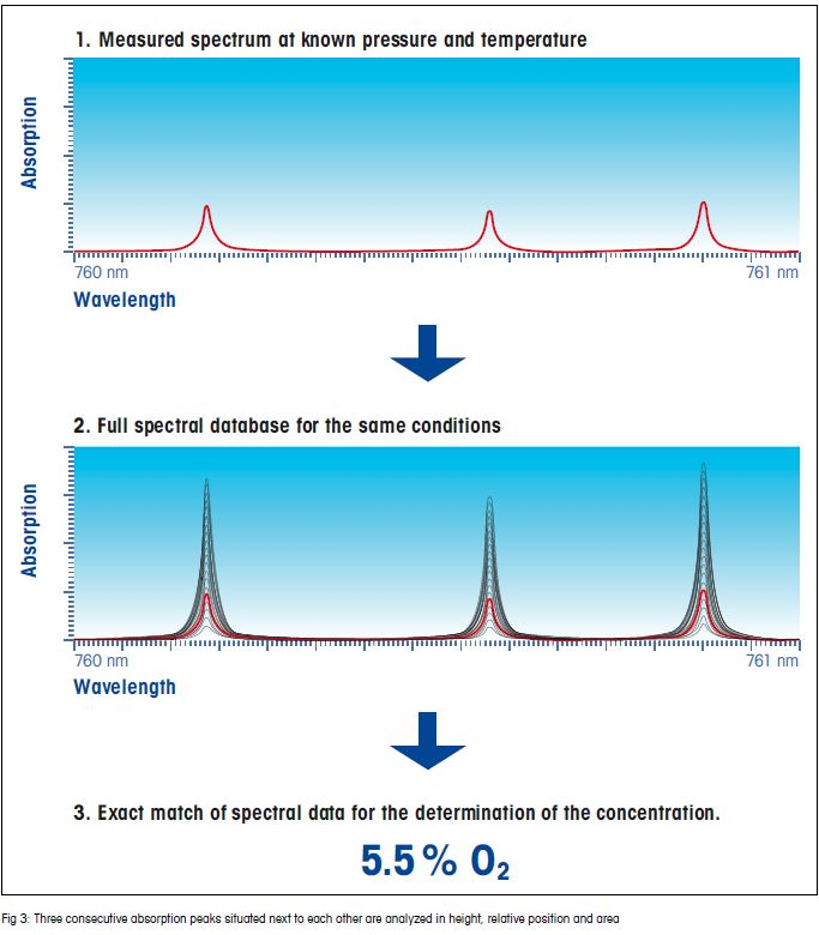

State-of-the-art TDLs for process and safety applications do not only make use of the latest advances in stable and long-lasting diode laser sources; they also profit from advanced signal processing algorithms that are able to cope with a wider range of process conditions and can deliver stable and reproducible concentration values. One key recent development concerns the issue of line locking, a general concern for TDLs where it must be assured that the wavelength range scanned by the laser diode exactly matches the wavelength range where the expected absorption peak is present, even after long periods of time where the TDL is powered but does not measure any gas concentration. With the SpectraID™ technology for oxygen measurement, three consecutive absorption peaks situated next to each other are analyzed in height, relative position and area. These results are then compared with a physical model of the absorption lines. If there is a match between the two sets of data then there is a perfect “DNA match” and it can be concluded that the observed absorption peaks are fully identified (see next page, Fig. 3).

Bright future

Tunable Diode Lasers are generating major interest due to their incomparable benefits for measurement reliability: absence of interference, long-term signal stability, and virtually no maintenance. From the supplier side, signs abound of a wealth of innovations that will further improve the user’s experience: easy installation and commissioning, and additional signal robustness are a few examples of recent improvements that are already available. Looking at near-future developments, certainly the commercial availability of laser diodes for the micrometer range will open new horizons to more gas species to be measured, making TDLs a true platform for gas analytics.

Contact Westech Industrial for more information on our Mettler Toledo product line or to find out more about getting a custom built sampling system please contact Westech Industrial at (403) 252-8803 or visit our website at https://bit.ly/370fb2S.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: BC Energy Faces a Complicated Puzzle – Margareta Dovgal, Resource Works