Pump minimum flow protects against overheating and cavitation, reducing maintenance costs and operational issues.

Cavitation and Flashing in your Centrifugal Pumps can lead to costly shutdown, loss of production and unknown repair costs, creating havoc on your bottom line. It is important to insure you have minimum thermal flow to pull the heat away from the pump internally to prevent cavitation and flashing.

Consider the 3 most commonly used pump protection methods:

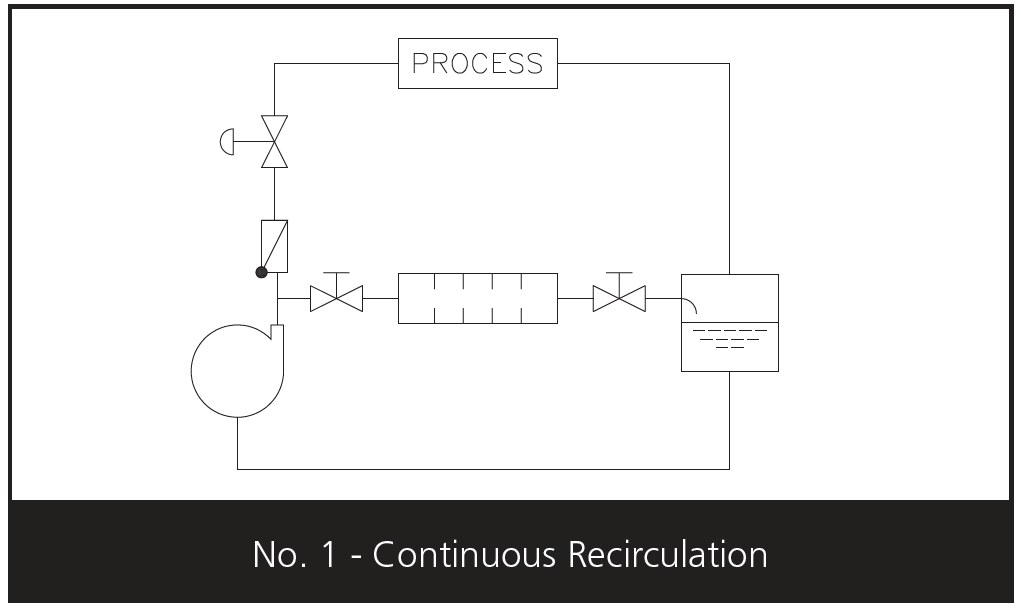

Continuous bypass (orifice only solution)

These systems continuously bypass the flow, which is required as a minimum to prevent overheating of the high pressure injection pumps.

- Minimum flows usually are approx.. 30% of the normal flow which could result in a tremendous energy loss.

- The pump to be selected is larger in size

- A pressure let down-system has to be provided for which is subject to cavitation and wear

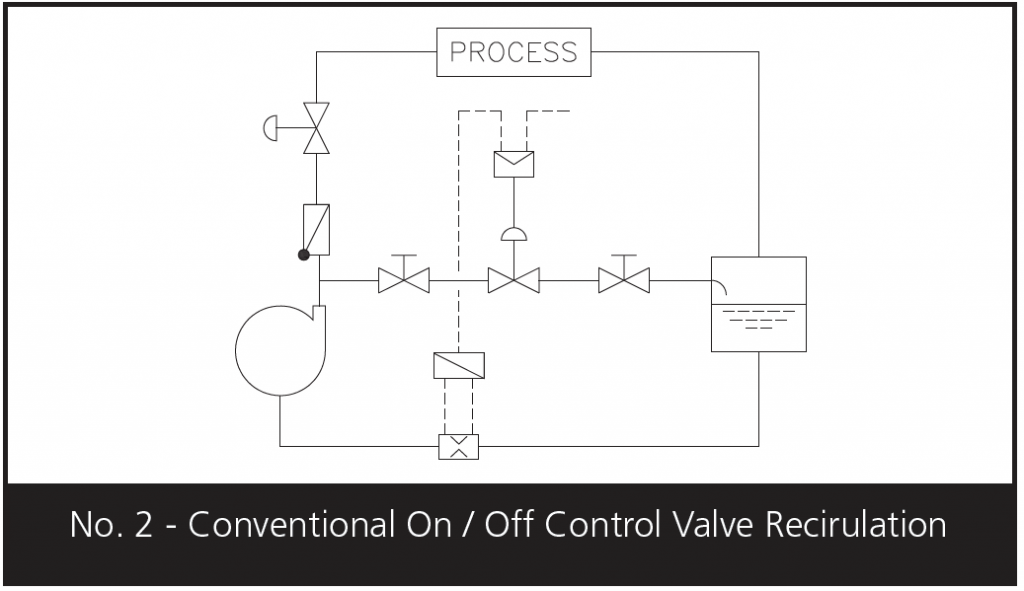

Controlled bypass systems with a control valve (CV Solution)

This system consists of:

- A control valve in the bypass

- A flow sensor in the flow system

- A control loop and a check valve located in the pump outlet creating more points of failure

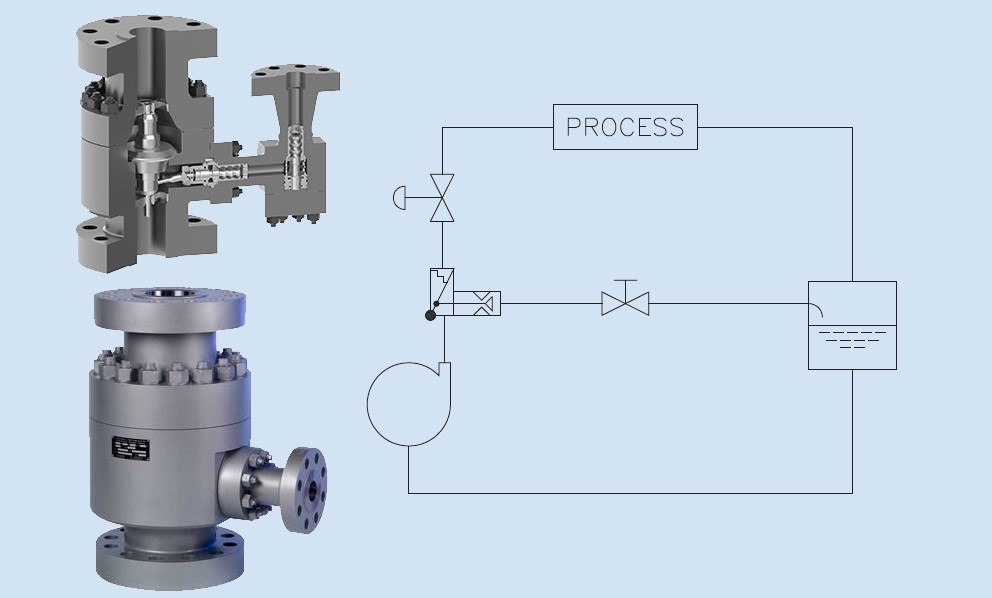

NO. 3 – SHCROEDAHL Automatic Recirculation Valve

Automatic Recirculation Valves from SCHROEDAHL are a simple solution to protecting your system.

The orifice, transmitter, controller, 3 way valve and check valve needed in the conventional methods are not required on the SCHROEDAHL ARV solutions.

- Maintenance costs are reduced and error sources are minimized

- A less complicated and more reliable system.

SCHROEDAHL – ARV TYPES

SUL Type (LP Service)

Max. PN #300 / PN 64

Cast body in CS and SS.

Max DN 250 / 10”

Bypass check valve as option.

Economic and suffcient design.

Option: With bypass check valve.

TDL Type (LP Service)

Max. PN #300 / PN 64 (except. #600)

Forged body.

Spring loaded bypass check valve

Variable flow control venturi ring design possible.

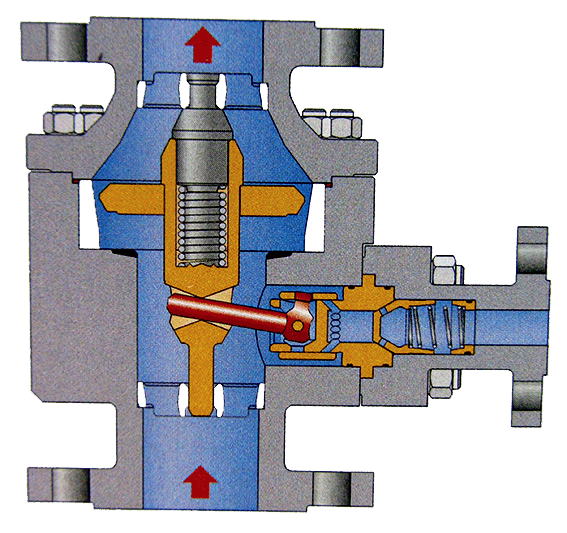

TDM Type (standard HP Service)

Max. PN #1500 (#2500) / PN 250 (400)

Forged body.

Bypass system with up to 5 control stages.

For HP feed service.

Bypass check valve function (>2 bar rp)

MRM / MRK Type (extreme HP Service)

Max. PN #4500 / PN 640 Forged body.

High pressure reducing bypass

system (up to 7 or up to 9 control stages).

For HP feed and offshore injectionn applications.

MRK: Bypass check valve function (>2 bar rp).

Find our more information

Please contact Westech Industrial for more information on our SCHROEDAHL Pump Protection product line at 1-800-912-9262 or visit our website at https://bit.ly/2J3k1CH

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Mike Rose – Canada Has All the Elements to be a Winner in Global Energy — Now Let’s Do It