Hydrotransport slurry pipelines are particularly susceptible to abrasive wear. High solids content, large particle size, flow stream velocity and corrosive fluids work together synergistically to attack and wear down pipeline materials. The pipelines transport a mixture of oil sand and process water from ore preparation plants – near the active oil sands mining area – to primary separation vessels, where bitumen is extracted from the ore.

Considering that pipelines are by their nature critical for this process, the operator approached ROSEN to find a solution that would reduce maintenance costs while increasing the assets’ life expectancy and reliability.

Traditionally these pipelines were constructed of carbon steel and included combinations of:

- Bare steel

- Steel with hardened or bimetallic materials

- Coated with layers of combined rubber and polyurethane

Given that these pipelines had been in operation beyond their useful service life, they needed to be replaced as soon as possible. Leaving the pipelines in their current condition could not only threaten production – due to unplanned shutdowns – but the integrity of the entire system.

THE SOLUTION

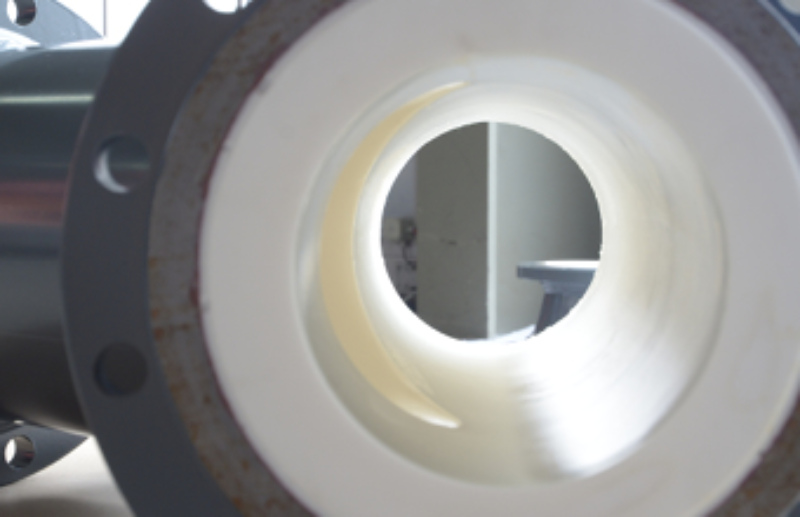

To ensure safe operation and longevity, ROSEN Intelligent Plastic Solutions supplied 2.1 kilometers of RoCoat 3000™ for the operator’s hydrotransport pipeline system. RoCoat 3000™, a polyurethane coating, was specifically designed for oil sands slurry pipeline applications. The proprietary formula delivers maximum life expectancy, and its superior adhesion to steel ensures reliable performance over time. The project included the manufacturing of 32” diameter pipe coated with 35 millimeters of RoCoat polyurethane. As is so often the case, the manufacturing of pipe was not the only need. With projects like this, time is of the essence! To deliver in a timely manner, ROSEN worked with the operator to define an optimal installation window and create an expedited project execution schedule to meet the operator’s needs and get the asset up and running!

THE BENEFIT

Upon accepting the accelerated project delivery, ROSEN immediately began working on executing the scope of work. The product was delivered on time to be installed during the next scheduled shutdown. In this hydrotransport slurry application, RoCoat has shown to provide reliable, long-term wear protection with reduced maintenance. RoCoat 3000™ delivers additional benefits to the operator:

- Extended operational lifecycle between five and 30 times

- Reduced maintenance cost by significantly extending maintenance intervals

- Outstanding wear resistance ideal for assets transporting oil sands products

- Superior adhesion to steel substrates, preventing disbondment

- Hydrocarbon and chemical resistance, ensuring compatibility with an operator’s process flow stream

- Elevated continuous operating temperature

Facts and Figures

Product: Oil sand hydrotransport slurry

Location: North of Fort McMurray, Alberta

Pipeline diameter: 32”

Total pipeline length: 2.1 Kilometer

Coating thickness: 35 mm

Visit www.rosen-group.com to learn more!

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Workers Must Be Part of the Energy Transition – Resource Works