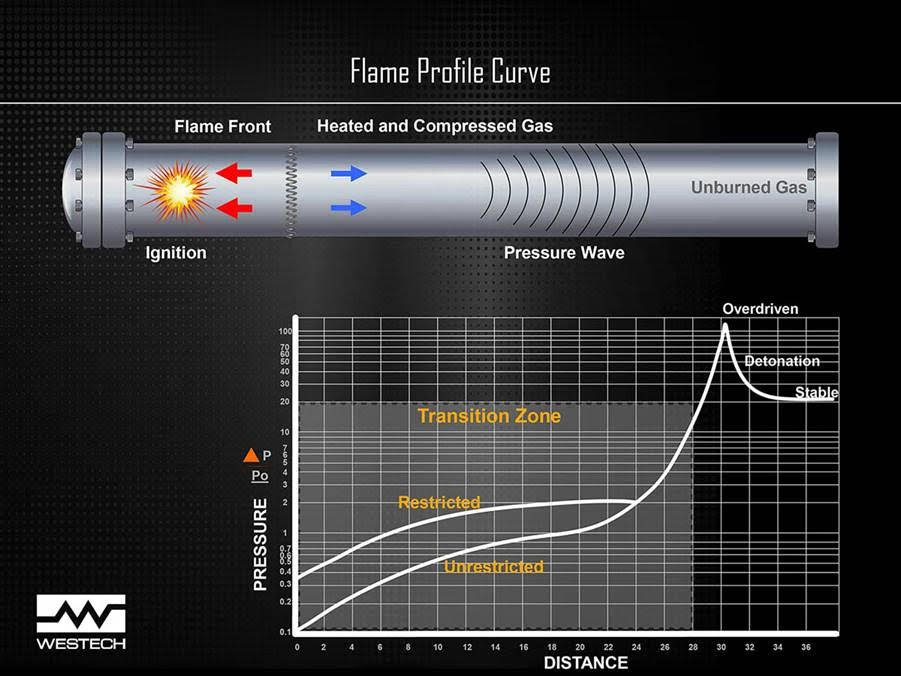

An unconfined atmospheric ignition of a gallon of gasoline on the ground produces a startling flame, strong pressure waves and a loud sound. When this same rapidly expanding combusted vapour is confined in a pipe, the flame front and pressure wave start travelling in the direction of the unburned gas. The combusted vapour expands to nine times its original volume, causing a jet effect and driving the deflagration to higher speeds and pressures. The flame front transitions through an explosion, from deflagration to overdriven detonation, reaching the peak pressure and speed. It then stabilizes and continues to travel through the piping system as a stable detonation.

Thus, a small, low energy ignition can be transformed within a very short distance and in fractions of a second into an enormous destructive force.

All confined explosions can be plotted to compare the pressure of the flame with the distance travelled. Every flame front that is not quenched will follow this flame profile with variations only to height and length, depending on several variables. Refer to the graph showing run-up distance and flame profile curve.

Westech’s in-line detonation flame arresters are designed and tested to stop travelling flame fronts under the conditions of low, medium and high-pressure deflagration, overdriven and stable detonations, and stabilized (long-term) burning on the arrester element. It can be installed anywhere in the piping system, regardless of distance from the source of ignition and the configuration of the same size piping system.

Westech Industrial has been working in the petrochemical industry for over 50 years and is a leading manufacturer of Inline Deflagration and Detonation Flame Arresters. The equipment quenches flame propagation through independent passive operation and allows for free vapour flow. There is a growing need for this product to reduce emissions of VOC’s (volatile organic compounds) into the atmosphere. This environmental benefit is achieved through flaring, incinerating or recovering the vapour.

Tested

Tested in Excess of Existing Standards, complete testing through the “Flame Profile Curve.” All Westech arresters are tested for actual field conditions not mandated by existing standards, including momentum impulse (long-run stable detonation), thermal failure and reignition of downstream unburned gases providing maximum protection against all modes of flame propagation.

Research & Design

Unrivalled Research & Design. Westech developed the test method “A Comprehensive Test Method for In-Line Flame Arresters,” which has been used as the cornerstone for all existing detonation arrester standards.

Our commitment to providing quality products ensures the safety and protection of your equipment and the people who run it.

To find out more about Westech Industrial’s Flame Arresters, please visit our website at https://bit.ly/3dNq5NO or call us at 1-800-912-6292.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS