Western Engineered Containment (WEC) is in discussions with a client who is trying to resolve leaks in a series of above ground lined tanks. The current lining method involves fabricating a polyethylene sheet liner into the cylindrical shape of the tank. As a result, effective seams at the junction of the wall and the circular base have been impossible. A reliable wedge weld cannot be done in an arc pattern, leaving less reliable extrusion welding as the industry practice. To accomplish this, the wall liner section extends a few feet onto the circular base liner to provide a flat surface for extrusion welding, but results in excess material gathering from the wall section of liner as a consequence. This material is pleated to complete the seam, and a complex shape needs to be extrusion welded as opposed to a standard single line. These complex welds represent the weakest construction points of the liner system.

WEC reproduced the extrusion welds of the pleated areas, making multiple samples. Some standard single line sections were also produced for comparison. 40 mil LLDPE was used as the liner, and 5 mm HDPE extrusion rod was used to make the welds. These seams were cut into 1’ wide samples and peeled apart in layers to test their integrity. An Instron Tensile Tester was used to analyze the samples.

Results:

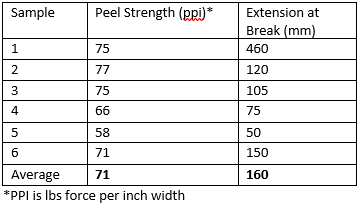

Single Line Weld

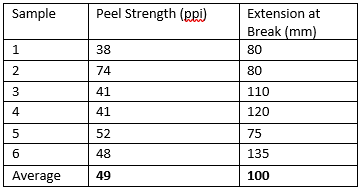

Pleated Weld, First Weld Bottom Layer (This is where the original 2 sheets are joined, the pleated section is folded a little behind and a little on top of this seam, resulting in 2 seams staggered a short distance from one another with overlap (see picture)).

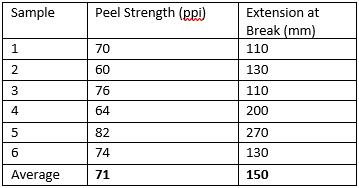

Pleated Weld, First Weld Top Layer (peeling the top sheet of the first weld, from the rest of the mass)

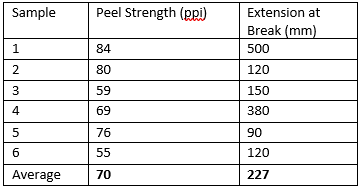

Pleated Weld, (Peeling pleat apart)

Conclusion:

The extrusion welds, and especially the complex pleated welds used in the above ground tank application are the weak point in the lining system. WEC is an experienced polyethylene installer, however, the production of extrusion welds in this configuration that consistently met acceptable industry minimum standards proved to be unachievable.

The replacement of the polyethylene lining system and extrusion welds with a spray applied seamless system would provide a much greater probability of eliminating leaks in the system.

If you would like to discuss this analysis further or have any other questions please contact the undersigned.

Sincerely,

Dave Martin, P. Eng.

Quantum Technical Services Ltd.

dmartin@quantumchemical.com

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS