Hydrogen is considered a key component of decarbonizing the world’s energy systems by replacing hydrocarbon fuel sources such as gasoline, diesel, and natural gas. While hydrogen has been produced and used in the petrochemical and oil industries for decades, its widespread use as an energy carrier has been limited.

However, global pressure to accelerate the transition to hydrogen is driving the development of the entire hydrogen supply chain from new hydrogen production methods, to hydrogen transportation and end use.

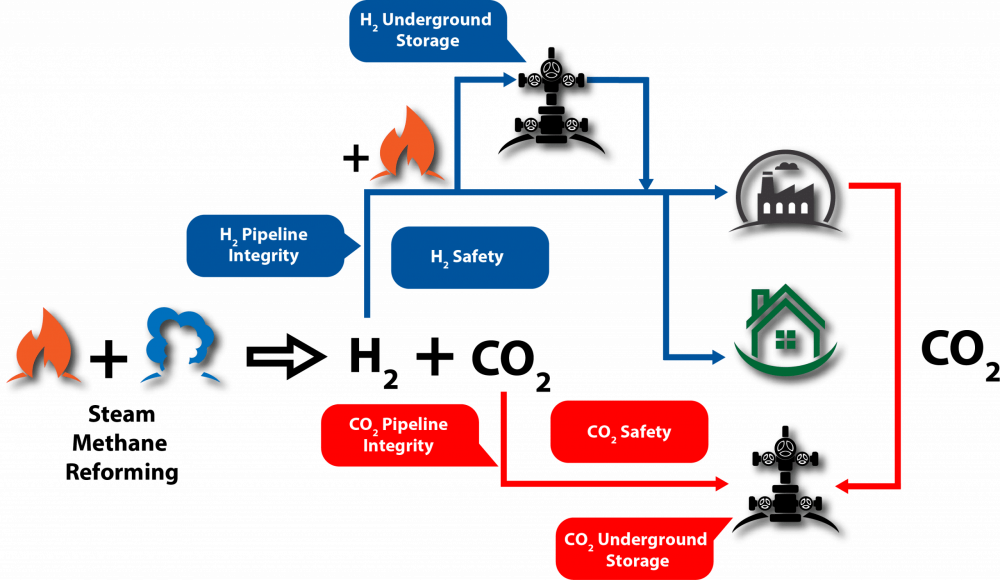

The most common, and lowest cost method for producing hydrogen is through the Steam Methane Reforming (SMR). This process uses natural gas as the feedstock and produces hydrogen and carbon dioxide. Capturing and storing the carbon dioxide from this process is required to minimize the greenhouse gas emissions.

Transporting hydrogen from where it is produced to end users is also a challenge. Trials are underway to blend hydrogen into existing natural gas pipeline networks for delivery to residential and commercial customers. Research work is underway to determine if hydrogen can be transported long distances in existing natural gas transmission pipelines.

Hydrogen Challenges

We are working with industry to evaluate and implement new technologies that will enable the widespread use of hydrogen. We are helping to develop new industry standards for hydrogen-ready equipment and to update industry codes and standards to ensure the safe transition to hydrogen.

Determining the feasibility of converting legacy natural gas pipelines to hydrogen service

- Advanced testing to determine material compatibility

- Small-scale tests with continuous exposure to pressurized hydrogen environments

- Full-scale testing of legacy pipeline segments with welds, dents and cracks

- Reliability-based assessment to determine remaining service life with hydrogen

- Crack growth rate estimation with expected operating pressure cycles

- Critical crack size and remaining burst pressure calculation

Ensuring that hydrogen can be transported and used safely

- Pipeline and facility release modeling to determine hazard zones for hydrogen and hydrogen blends

- Overpressure threat evaluation from hydrogen ignition

- Heat radiation modeling for jet fires

- Confined release modeling inside buildings and homes for hydrogen and natural gas blends

- Gas accumulation dynamics in enclosed spaces

- Probability of ignition considering flammability limits

Validating the design and construction of hydrogen storage wells

- Storage well pressure integrity evaluation

- Gas-tight seal performance testing for storage well casing, tubing and wellheads

- Wellbore cement permeability evaluation

- Casing and tubing inspection to determine remaining life of corroded and deformed wellbores

- Storage well servicing procedures and equipment performance

- Well intervention procedure risk assessment

- Safety valve and blow out preventer functionality

Validating the design and maintenance of CO2 pipelines

- Confirm fracture toughness requirements to prevent fracture propagation in dense-phase operating conditions

- Confirm fracture toughness of pipeline materials

- Fracture propagation and arrest evaluation

- Assess viability of converting legacy pipelines to CO2 service

- Determine maximum operating pressure for legacy pipelines with defects

- Estimate remaining life considering defect growth and defect management activities

Supporting development of a CO2 collection and transportation network

- Assess the risk associated with CO2 pipeline and facility operations

- Model CO2 releases to determine life safety and environmental impacts

- Evaluate the impact of impurities on the behaviour of the CO2 releases

Ensuring the long-term integrity of CO2 storage wells

- Validate well equipment and materials for storage well construction

- Gas-tight seal performance testing for storage well casing, tubing and wellheads

- Long-term wellbore cement performance in an acidic environment

- Casing and tubing inspection to determine remaining life of corroded and deformed wellbores

- Apply a quantitative risk assessment framework for releases from storage reservoirs

- Consider configuration and condition of legacy wells in creating leak paths

- Evaluate consequences of sub-surface and atmospheric releases

Applying C-FER’s Expertise

Hydrogen Technology Challenges

Resolving technical challenges to enable the widespread use of hydrogen.

Assessing Indoor and Residential Risk

Understanding how hydrogen-natural gas blends behave in indoor and residential environments.

Marine Transportation of Hydrogen

Assisting GEV Canada to assess the feasibility of constructing a ship capable of transporting up to 2000 tonnes of pressurized hydrogen.

Legacy Pipeline Compatibility with Hydrogen – Joint Industry Project

C-FER is launching an industry-leading, multi-phase joint industry program to better understand the viability of using legacy pipeline networks for blended or pure hydrogen service; a concept that was developed in partnership with Sumitomo Corporation of Japan.

This program will engage global pipeline and hydrogen industry stakeholders to establish safe hydrogen blend thresholds for a range of legacy pipeline materials and vintages.

It will also develop methods to evaluate the performance of in-service pipelines based on combining historical material test data with medium- and large-scale tests of line pipe specimens in continuous hydrogen environment exposure.

Learn More!

For more about the project and for details on the project phases, visit the Joint Industry Project page.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

Canada’s Advantage as the World’s Demand for Plastic Continues to Grow