Leak detection in injection well system and in pipeline gathering systems is becoming increasingly important to all stakeholders in the oil business. Producers are keenly interested in matters such as environmental stewardship, managing insurance premiums, and maintaining relationships with the Alberta Environment Regulator. Automating the leak detection process is one very effective way to meet the goals of all the stakeholders. Automated systems detect leaks in minutes and are vastly superior to the manual method of sending personnel on daily visits to check meters in the field.

Producers are also keenly interested in managing the costs of leak detection, particularly now when capital is extremely scarce. Automated leak detection systems have traditionally been developed using field-based SCADA systems. These systems can be effective, but they are typically very expensive to install and maintain. This is partly due to the cost of installing and maintaining the radio networks which are commonly used to facilitate the peer to peer communications in field based SCADA networks. One drawback to field based systems is that alarm limits are typically hard coded, leading to a high incidence of false alarms.

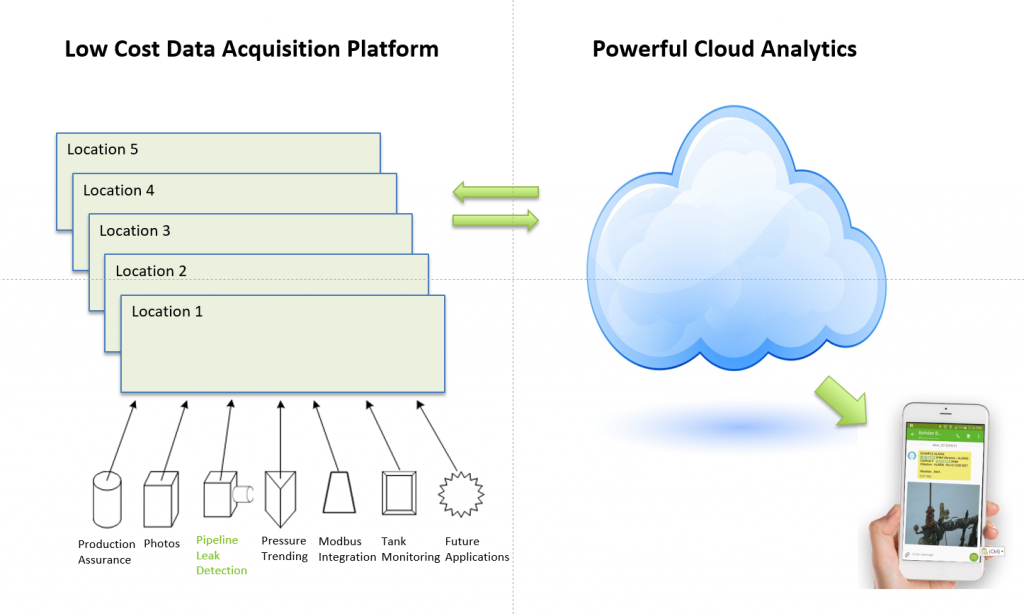

With the increasing availability of cell towers and the rapidly dropping cost of data communications in cell networks, producers can now take advantage of an approach for leak detection which is inherently less expensive and more powerful. WatchDog, manufactured by Calgary based AFTI, is a simple but powerful platform for capturing and analyzing oilfield data. WatchDog’s architecture minimizes infrastructure (and therefore cost) by focusing on acquiring data in the field and computing in the Cloud. This allows WatchDog’s leak detection application, which works on both injection wells and gathering systems, to provide producers with powerful and accurate leak detection capabilities at a cost which is substantially lower than traditional solutions.

In order to provide effective leak protection, a solution must provide two attributes: The ability to detect small leaks quickly, and sufficient intelligence to minimize false alarms. The WatchDog architecture delivers these results.

Almost all other leak detection systems simply trigger an alarm based on a comparison of single readings (such as the delta between the source and the destination flowrates). WatchDog monitors the true long term relationship between the source and the destination flowrates. It then uses complex mathematical algorithms to determine when this relationship has changed in a way which indicates a true leak. Users can configure minimum and maximum limits for each zone within the field, for example setting a corporate-wide limit on the largest or smallest leak which will produce an alarm message.

In summary WatchDog provides more accurate detection of smaller volume leaks and minimizes the instances where false alarms are generated.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS