Casco’s FR-1002 is a nano-composited, nonionic, high performance friction reducer that is designed specifically for hydraulic fracturing. In contrast to other friction reducers, FR-1002 has the following characteristics:

- Unlimited salinity resistance

- Handles extremely harsh brines containing saturated levels of Ca, Mg and Fe.

- 100% biodegradable, green friction reducer.

- Water soluble, does not block the formation or cause damage to the formation like conventional friction reducers.

- Compatible with common fracking fluid ingredients.

- Can also be used in deep well applications to increase flow and decrease pump pressure.

KEY PERFORMANCE INDICATORS

Percentage Friction Reduction (1GPT):

In tap water @ 25 ºC: > 70% (up to 78%) In tap water @ 70 ºC: > 70% (up to 78%)

In 10% calcium chloride: > 70% (up to 78%) In flow back water: > 70% (up to 78%)

In seawater: > 70% (up to 78%)

@-17ºC (1ºF) for 3 days: not frozen; friction reduction afterward > 70% (up to 78%)

@-80ºC (-122ºF) for one week: frozen; intact after thawing with friction reduction > 70% (up to 78%) After hot rolling @130ºC (266ºF) for 8 hours: friction reduction > 70%

Regained Permeability (core analysis; 24 hr.):> 99% (In contrast to < 2%)

Eco-toxicity: non-toxic; EC50 >1.00 x106 mg/L

Case History 1

Stimulation by FR1002 only for horsepower saving and Production improvement

Formation: Olmos, Bear Creek Field, Sandstone

Location: Medina County, TX

True Vertical Depth to Middle Perforation: 2,203 ft.

Reservoir Temperature: 115 °F

Pumping Rate: 15 BPM through 4-1/2” casing

Liquid Production before Stimulation: 1-2 bpd

Expected Production after Stimulation: 3-4 bpd

RESULTS:

- Pumping pressure/horsepower was cut by 45%

- Liquid production was up to 36 bpd with an enhancement of 18-36 folds

- FR1002 is 10 times more effective than that of guar gels or regular slick waters

Case History 2

Well Clean Out via Coiled Tubing

Field: Sichuan Basin, P.R.C.

Operation: Comparative clean-out via coiled tubing by utilizing FR1002 vs a conventional dry powder friction reducer (abbreviated as “FR-A”).

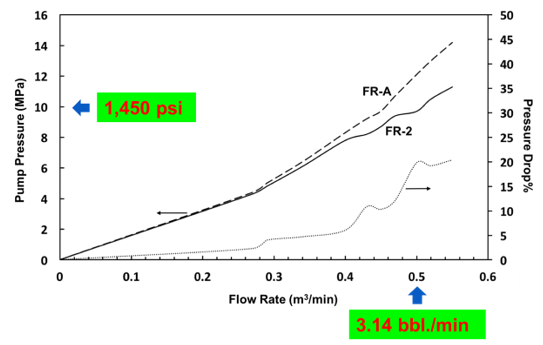

Results: The use of FR1002 led to up to 20% lower pumping pressure than conventional dry powder FR (FR-A) (see Figure 1 below).

- When pumping rate was 0.2-0.3 m3/min (53-80 gallons/min), the two friction reducers made no significant difference

- With pumping rate increased to 0.55 m3/min (145 gallons/min), the pump pressure was 11MPa (1,595 psi) when using FR-1002 and 14MPa (2,031 psi) when using FR-A

- The gap (difference in pump pressure) increased further with the increase of pumping rate (greater than 0.55 m3/min or 145 gallons/min)

Figure 1. Pumping pressure by FR-A & FR-1002 during a well clean out via coiled tubing; dashed line: FR-A; solid line: FR-2; dotted line: pressure drop% by FR-2 (in comparison with FR-A).

Case History 3

Horizontal Fracturing/Same Well, Same Stage

Field: Sichuan Basin, P.R.C.

Operation: Comparative fracturing on the same stage utilizing FR-1002 vs a conventional dry powder friction reducer (FR-A).

Results: Use of FR-1002 has achieved 10% pumping pressure reduction than conventional dry powder friction reducer (FR-A) (see Figure 2 below).

- Pumping rate: 12 m3/min (3,170 gallons/min or 75.6 bbl./min)

- Lowest pump pressure of 52MPa (7,542 psi) achieved when using FR-2

- Before/after FR-1002, average pump pressure was 57.4MPa (8,325 psi) & 54MPa (7,832 psi) respectively

- A pumping pressure reduction of up to 10% using FR-1002

Figure 2. Pumping pressures before, during and after the use of FR-2 during a horizontal fracturing (pumping rate: 12 m3/min or 75 bbl./min); before and after FR-2, a conventional dry powder friction reducer FR-A was in use.

Case History 4

Horizontal Fracturing/Same Well, Different Stages

Field: Southwest China

Operation: Comparative fracturing on different stages of the same well utilizing FR-1002 & a conventional emulsion friction reducer.

Results: The use of FR-1002 led to additional 8% pumping pressure reduction than conventional emulsion friction reducer (see Figure 3 below).

- Pumping rate: 11 m3/min (69.2 bbl./min)

- An additional pumping pressure reduction of 8% by FR1002 was the result

Case History 5

Daily Gas Production Enhancement

Field: Sichuan Basin, P.R.C.

Operation: Comparative daily gas production through two wells on the same platform [one fractured by FR1002 (Gas Well #1); the other by a conventional inverse emulsion FR (Gas Well #2)] (see Figure 4 below).

Results: FR1002 is three times more effective at curtailing daily gas production decline than conventional inverse emulsion FR.

- Gas well #1: decline rate was ca. 10% after three months of production

- Gas well #2: decline rate was ca. 30% after three months of production

- Literature reports ca. 30% decline after three months of gas production on 838 wells (see image to the left in Figure 4)

Figure 3 & 4. Left Image (3): from literature reporting on an average gas decline of ca. 30% after three months of production; Right Image (4): comparative declines by FR1002 (10%) and a conventional inverse emulsion FR (30%).

Case History 6

Vertical Fracturing (Guar Gel vs. FR1002)

Operator: A Super Major;

Field: Xinjiang Region, P.R.C.

Operation: Comparative fracturing on the same interval (6525.8 – 6630.0 m or 21,410 – 21,752 ft.) utilizing linear guar, crosslinked guar and FR1002

Results: FR1002 led to a free fall of pumping pressure in contrast to conventional linear and crosslinked guar gels.

- Pumping rate: 0~4.8 m3/min (1,268 gallons/min or 30.2 bbl./min);

- At a pumping rate of 2.0 m3/min (12.6 bbl./min), the average pressure by linear gel was 60 MPa or 8,702 psiAt a pumping rate of 2.0 m3/min (12.6 bbl./min), the average pressure by FR1002 was 13.5 MPa or 1,958 psi (a 78% decrease)

Casco is a subsidiary of Petro China which manufactures a variety a specialty and commodity chemicals in China for import into Canada and the United States. With locations China, Edmonton and Nisku, Alberta, and Houston Texas. Products include the following:

Specialty Chemicals

- Drag reducing agent for oil pipeline transmission

- Demulsifiers (intermediates or finished products)

- Specialty friction reducers for hydraulic fracking

- Pour point depressants (high activity, freeze-resistant)

- Specialty defoamers and foamers for oil and gas production

- Flooding polymers

- Acid corrosion inhibitors

- Scale Inhibitors

- Water treatment polymers and additives

- Specialty Surfactants for oil and gas production

The above list shows CASCO’s top sellers only. For those that are not currently on this list, CASCO can competitively source for you.

Commodity Chemicals

- Acetic acid

- Carboxyl Methyl cellulose (CMC)

- Caustic soda

- Choline Chloride 60%, 70%, 75%

- Citric acid

- DADMAC / Poly DADMAC

- DDBSA

- Ethyl cellulose (EC)

- Ferric sulfate (Tech grade)

- Formic acid

- Glyoxal, 40%

- Graphite

- Hydroxy Ethyl Cellulose (HEC)

- IPA

- KOH

- Octyl phenol

- PASP

- Polyanionic cellulose (PAC)

- Potassium acetate

- Potassium formate

- Propylene glycol

- Sulfamic acid

- THPS/THPC

- Sodium Metasilicate

CASCO can customize any oilfield specialty chemicals for applications from downhole to refinery. Economic pricing and high performance are guaranteed.

Contact CASCO Ltd.

Shelley MacCallum

Operations Manager

Casco Chemicals

780-850-4656

smaccallum@casco-chemicals.com

www.casco-chemicals.com

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

Canada’s Advantage as the World’s Demand for Plastic Continues to Grow