STEP Engineered Pipeline Services

A new Alberta pipeline system under construction relied on STEP Energy Services for technical support in its safe hibernation while waiting for system commissioning. STEP was chosen to support this important hibernation phase because of STEP’s safe work procedures, personnel experience in pipeline hibernation, commissioning and engineering simulation techniques that predict the control of corrosion inhibitor application, complimented by nitrogen inerting of the system.

Discussion

The hibernation of a new pipeline systems takes special consideration in safely batching corrosion inhibitor within the void system to provide circumferential coverage of the inhibitor at a target dose rate. The prediction and control of the corrosion inhibitor/nitrogen gas interface of a new and void system is paramount to delivering the inhibitor batch.

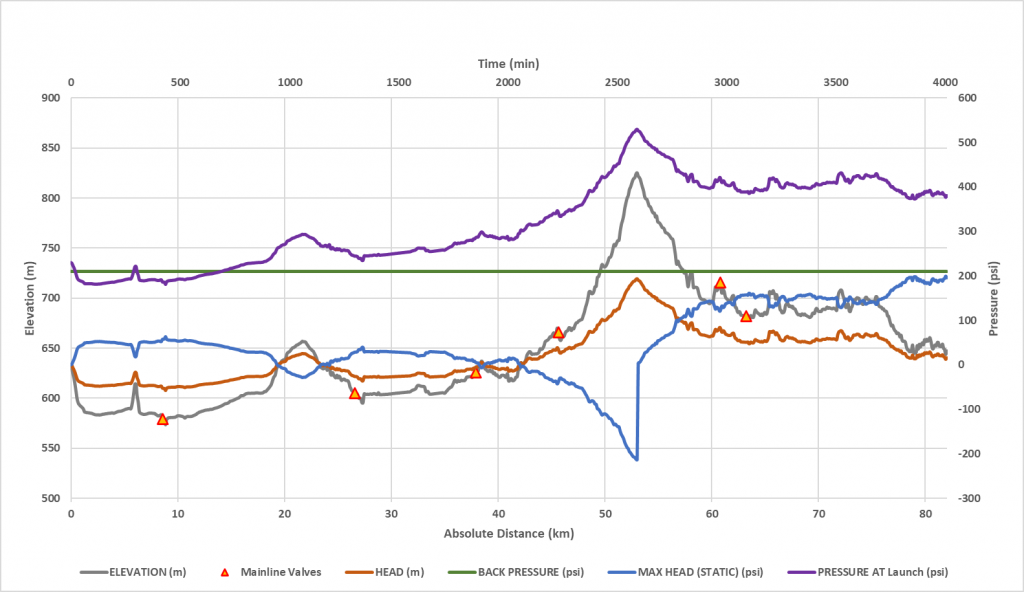

Understanding the weight of the liquid column of the corrosion inhibitor, the flow characteristics of the filming material, and recognizing and accounting for the depletion of the liquid column as the inhibitor is filmed to the pipe wall are integral to controlling back pressure on the void system. Additionally, this understanding is a pre-requisite to the required pressure and rate of nitrogen gas to smoothly traverse the inhibitor batch across the system.

A carefully thought out hibernation plan will optimize the rate of nitrogen injection to achieve the target dose of the inhibitor. Additionally, the plan will guide the pipeline operator to crucial pressure/chainage points where pre-determined back-pressure must be developed to tightly control the inhibitor column in dynamic condition particularly in regions of elevation decent; this is important to ensure circumferential displacement of the inhibitor. With the use of task and flow modelling, the engineered hibernation program is capable of discrete adjustments to the program which accounts for changes in elevation, fluid characteristics, flow rate, temperature, valve location and type, and receive point characteristics.

Recommendations made to the execution plan for hibernation must consider the main line valve control characteristics, pipeline wall thickness changes, system pressure and flow indicators, pig signal devices and the receiving point of the inhibitor batch. Lastly, consideration is given to leaving the inhibited system in an oxygen-free state with nitrogen gas, and with enough pressure to aid the commissioning of the system when that step occurs.

STEP Energy Services – Leadership in Pipeline Hibernation

With a new pipeline system nearing completion of construction, STEP collaborated with the operator to review critical details of the 160-kilometer pipeline to design a hibernation program for the unique system. The purpose of hibernating this system was to create a corrosion free environment post hydrotest, while awaiting commissioning. The operator sought best-in-class rationale for preserving their pipe as it was not known how long the system would rest idle.

Being an industry leader in nitrogen pumping services for pipeline application, STEP judiciously applies inert nitrogen gas in pipeline hibernation programs to provide an environment that mitigates oxygen for corrosion control and resulting in a pressure condition that compliments the commissioning of the system.

STEP conducted a thorough analysis of the pipeline system and recognized the opportunity to conserve resources by inhibiting multiple lines of the system from the same location by staging check valves to allow safe passage of the inhibitor and nitrogen batch. This recommendation provided an economic benefit by reducing the costs associated with mobilizing to multiple separate locations. The operator realized a 10% reduction in the volume of nitrogen gas required for back pressure control on the subsequent pipelines, plus additional savings in personnel and equipment time that would otherwise be incurred during the venting of the each system.

After analysis of the elevation profile and inhibitor batch characteristics, STEP worked closely with the operator and the inhibitor vendor on nitrogen displacement rate to ensure uniform delivery of the inhibitor batch by applying back-pressure controls ahead of the delivery. Furthermore, in designing a predictable inhibitor delivery program STEP collaborated with a specialty pig manufacturer in the supply of a fit-for-purpose inhibitor batch pigs tailored to the filming inhibitor characteristics. The goal was to apply a well sealing lead pig that resists back-pressure gas from by-passing into the inhibitor batch while, at the same time, providing constant velocity by nitrogen injection to allow the rear filming pig to evenly coat the pipe wall in dynamic state.

STEP Energy Services – Importance of a Well Designed Hibernation Program

Hibernating a pipeline system is a step that requires attention to detail and early engagement with a trusted service provider. In summary, the key consideration of a successful hibernation plan include:

- ensuring the delivery of the corrosion inhibitor at the correct dose and circumferentially displaced in the pipe;

- a thorough analysis of the pipeline elevation profile and as-built physical characteristics to ensure predictable delivery of the inhibitor batch; and,

- using nitrogen gas to motivate the inhibitor batch reducing oxygen content in the pipeline further mitigating corrosion while the pipeline is idle;

- maintaining a positive pressure pad of nitrogen on the pipeline system while idle as this will provide an inert atmosphere for back pressure control during filling.

Learn more about STEP Energy Services and industrial nitrogen services by visiting: https://www.stepenergyservices.com/services/midstream-downstream-solutions

For an engineered solution to your upcoming pipeline hibernation program, please contact STEP at one of the following facilities:

FORT ST.JOHN, BC

6711 87A Avenue

Fort St. John, BC

V1J 0B4

Phone: 250-787-8812

Dispatch: 1-855-480-STEP (7837)

GRANDE PRAIRIE, AB

10202 88 Avenue

Clairmount, AB

T8X 5G8

Phone: 780-830-0684

Dispatch: 1-855-480-STEP (7837)

RED DEER, AB

30 Burnt Bluff Street

Red Deer, AB

T4P 0J6

Phone: 403-406-6002

Dispatch: 1-855-480-STEP (7837)

SAN ANTONIO, TX

70 NE Loop 410

Suite 1070

San Antonio, TX 78216

Phone: 210-477-1517

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Workers Must Be Part of the Energy Transition – Resource Works