PIT’s answer to simple, smart, optimized fluid level reading is brought forward with the FL3. The FL3 is a simple, easy to use tool used to gather downhole fluid levels and pressure measurements. Users can quickly optimize pump speeds to get the most from their well and protect the pump in the process. Functional as a portable or permanent fixture on your well, the FL3 utilizes 2-way remote control features to increase value and safety.

We have mastered cloud computing to achieve a user-friendly experience where anyone can find more oil and bring more life to their pump. While the FL3 can gather Fluid Level and pressure data, it is also capable of reading and connecting to other well or lease devices. From these, it gathers data and details the well’s needs. All this information is gathered instantly and analyzed remotely using PIT’s Cloud Data Connection.

The FL3 Smart Fluid Level Machine does much more than fluid levels and pressures, allowing operators to make more informed decisions to find more profit in every sell.

A Case Study Success Story

In working with a prominent oil company that wishes to remain anonymous, PIT conducted a 12-week trial on two wells in a Polymer Flood Heavy Oil Field. The results were overwhelmingly successful. Thanks to the FL3’s reliable fluid level measurement and the pump’s available pressure calculations, the two wells were safely optimized and achieved maximum production rates.

As a result, the pump was protected during the many inflow fluctuations in this polymer flooded mature oilfield and the oil production was uninterrupted. Previously, these wells had experienced costly premature pump burnouts and downtime due to the difficulty of gathering accurate fluid levels. Existing, conventional fluid level machines and pump off control devices had cost this company valuable resources and money.

Using Smart Technology to Capture Fluid Levels Without Noise

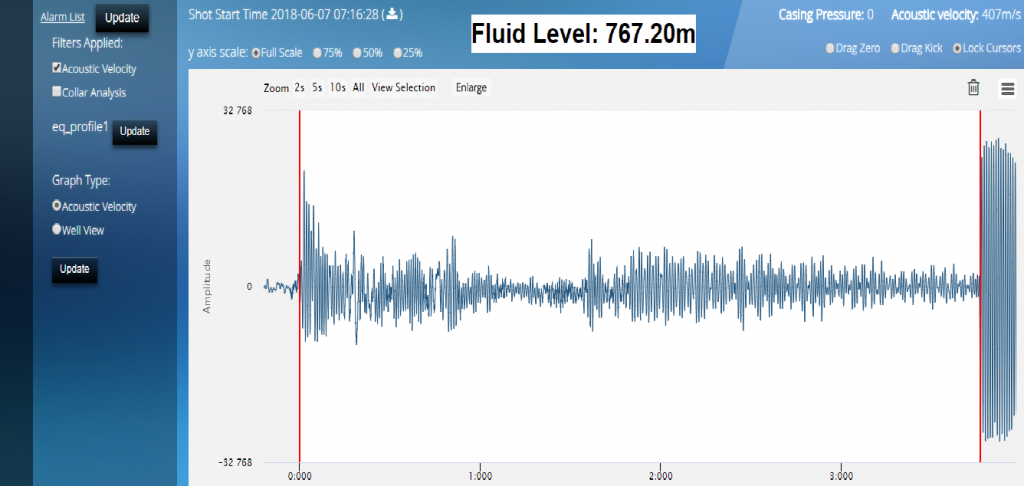

Using PIT’s efficient special wellhead attachment, the fluid level determining sound waves were sent down the well. The wellhead attachment makes use of a small bottle of Nitrogen to generate these sound waves. Each bottle of Nitrogen lasted the company 12 weeks and created over 300 separate measurements of current fluid levels. Due to the high quality of the FL3’s data capturing system, fewer shots were required to obtain the inflow data when compared to other fluid level devices.

These wells are considered “noisy” due to their PCP Rotary Pumps. Traditionally, accurate and reliable fluid levels on these types of wells are extremely difficult to obtain. Additionally, these case study wells were producing 1500-1900 barrels of fluid per day and possessed a horizontal leg. These elements made the wells excellent and challenging candidates to test PIT’s new Smart Fluid Level technology.

The FL3 was used daily via remote from the Oil Battery office by the client’s well operators, and occasionally by the engineering staff.

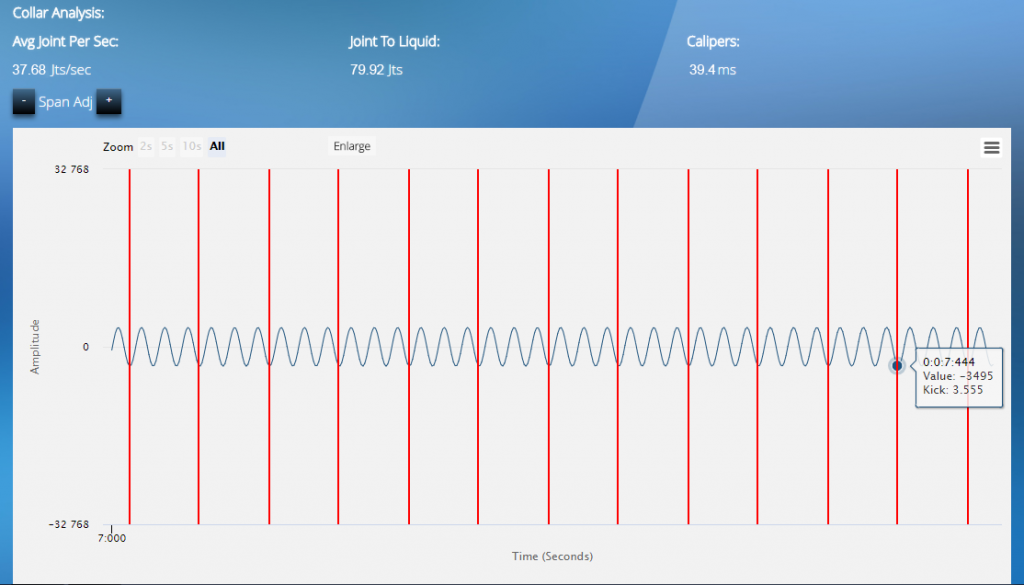

Historically, older fluid level machines gathered data from Oil PCP Pump wells and the data gathered typically looks noisy and imprecise. These readings make it incredibly difficult to see tubing collars or the fluid level.

By making use of the FL3, the system uses its smart technology to process and automatically clean the data and identify the correct fluid level.

Additionally, the FL3 can deliver detailed collar data.

Interested in Premier Integrated Technologies Solutions? Visit premiertech.ca for more information!

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

Canadians Should Decide What to do With Their Money – Not Politicians and Bureaucrats