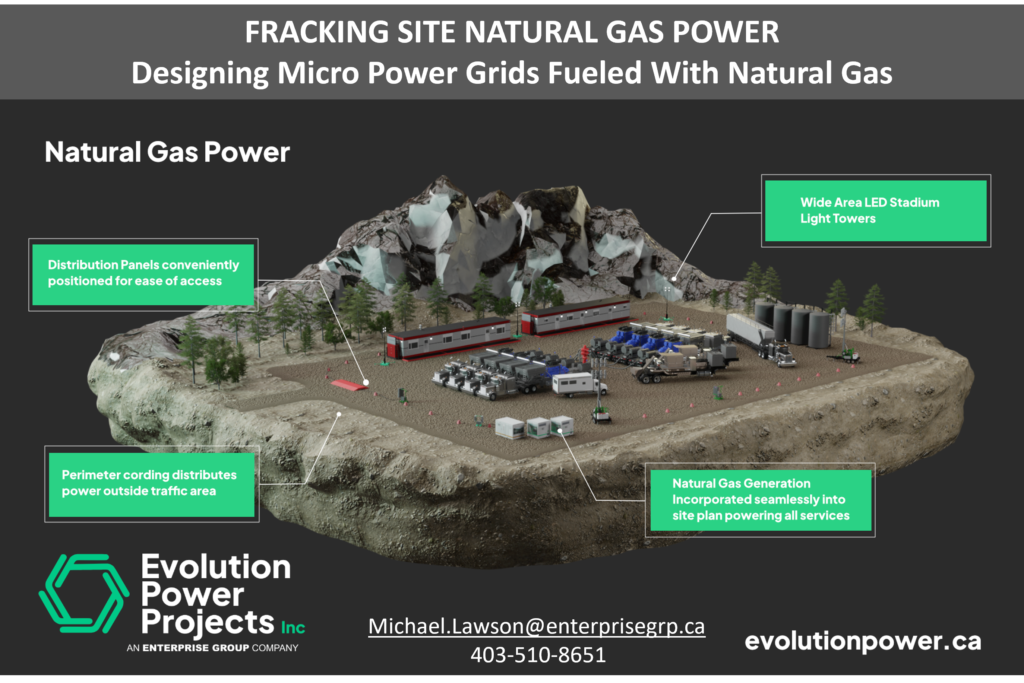

Calgary, AB – A microturbine generator on the market is transforming operations in the Canadian energy sector. More and more Operators are using their own fuel gas and natural gas to power drilling and completion pad sites, aiming to lower or eliminate the costs associated with diesel or bifuel and to meaningfully reduce emissions. Along with a microgrid, multiple microturbines can be paired to match the various power needs of a remote project site. Typical uses for these mobile systems are powering lights, shacks, datavans, pumps, wireline units, and other third-party support equipment.

“Operators are now using their own production to power drilling and completion ancillary gear on-site,” stated Mike Lawson, Vice President of Enterprise Group, Inc. In water management applications, Operators are switching from diesel power generation at primary water sources to power fracs and heat reservoirs, among other uses. “Fuel gas or natural gas power applications greatly reduce their diesel costs, transportation of diesel, refilling expenses, spillage costs, and emissions,” he further noted.

A leading Canadian oil and gas producer chose Evolution Power Projects Inc., (a wholly owned subsidiary of Enterprise Group) to set up and manage the same fuel gas turbine in Central Alberta, using it to combust flare gas at one of their production facilities. In October 2024, they effectively deployed three 333kW fuel gas turbines, combusting approximately 10 decs of gas per day to facilitate oil flow and minimize emissions while generating nearly 1 megawatt of usable power. The company also noted that Operators are now selling the generated power back to the grid, mining for bitcoin, and utilizing the generated power and heat for various other applications.

Evolution Power Projects emphasized the significance of this achievement, noting, “Firstly, it allows us to help a client capitalize on surplus natural gas production in areas with limited infrastructure. Secondly, our advanced turbine technology offers Operators and Midstreamers an innovative solution to comply with strict flaring and emission regulations effectively.” Operators can now safely and responsibly combust flare gas to efficiently flow production wells in areas with limited infrastructure and where flaring is prohibited.

Evolution Power Projects has noted an increase in inquiries for using its turbines to power pump jacks, compressor stations, gas lifts, and various other applications due to its industry leading turbine fuel tolerance capabilities. The turbines can also operate on propane or natural gas with up to 6,500 ppm of sour gas (H2S) content, which is a significant feature. Furthermore, Evolution Power Projects mentioned that the turbines come equipped with built-in load banks, offer 24/7 remote monitoring, experience nearly zero downtime, and require only 8 hours of maintenance annually.

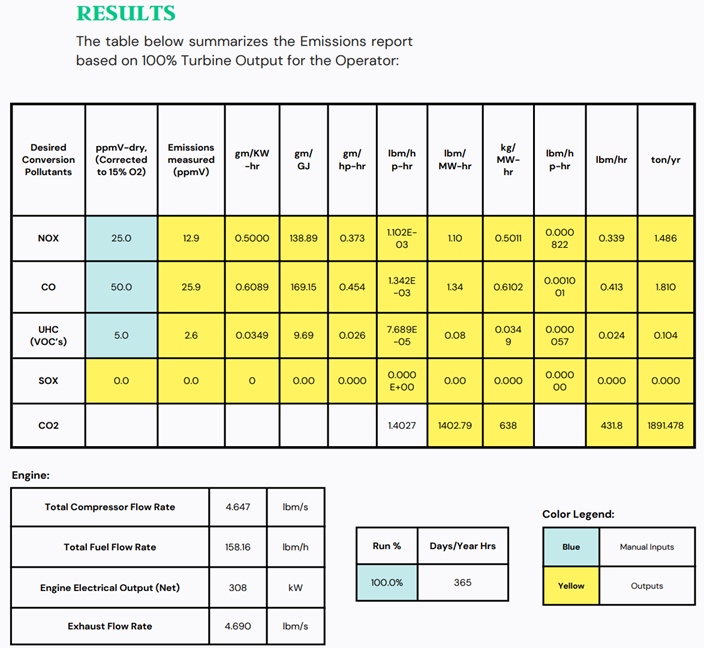

The Operator performed an emissions test on the turbines using their flare gas, the results of which are shown in the table below.

CLICK HERE for the entire Case Study

More About Evolution Power Projects

Evolution Power Projects is reinventing the way mobile power is provided on site. This in the interest of developing efficiencies, streamlining generator rentals management, supporting critical services and promoting natural gas alternatives.

Their Concept to Completion Approach assists their customers in evaluating their overall power demand and offer innovative, low carbon, environmentally responsible options.

Evolution Power is Leading the way by advancing the Natural Gas to Electricity methods of mobile power supply. They have over ten years experience optimizing electrical distribution and technology development.

They deliver value to our customers through emission reduction technology and support their ESG initiatives.

Natural gas electrification is the future of the energy evolution. Cleaner, quieter, safer and most importantly – Measurable.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS