Even though Canada’s overall construction season starts to wind down as temperatures dip, road and pad construction projects shouldn’t have to! Winter and spring construction often pose significant challenges—frozen subgrades, compaction issues, and increased crew operating costs—but there is a viable alternative to traditional construction: Tough Cell® NPA geocells.

Tough Cell® geocells give contractors a robust solution to build smartly, sustainably and more cost-effectively during winter and spring. Roads no longer have to succumb to the pressures of freeze-thaw, and construction no longer has to be stunted by compaction issues.

Pad Construction with Frost on the Ground.

What makes Tough Cell® geocells the BEST option on the market?

Superior Material Composition

- Unlike HDPE geocells, Tough Cell® geocells are made from an advanced polymeric alloy with high tensile strength that can withstand an extensive temperature range (-60°C to +60°C) without losing its strength or becoming brittle.

- Its high creep resistance ensures consistent load distribution even under prolonged exposure to cyclic freeze-thaw conditions. Tough Cell® has a tested creep (deformation) of less than 3%. Plastic deformation can occur above 3%, causing cell wall expansion and compaction loss, leading to a loss of confinement and the potential for failure. This is a common issue with HDPE geocells that Tough Cell® technology overcomes.

Quick Installation requiring Minimal Ground Preparation

- Winter conditions often constrain ground preparation due to frozen soil layers. Tough Cell® geocells require significantly less (if any) subgrade preparation compared to conventional construction methods. It is tried and tested time and time again for building over frost heave and soft soils such as deep peat and muskeg.

- Tough Cell® geocells are easily adaptable to most ground conditions and can be deployed quickly- roll out, expand and fill!

Time and Cost-Efficient Solution

- Installing Tough Cell® requires less time thus saving on manpower and project management hours.

- It can save 40% to 50% aggregate fill quantities and be infilled with recycled aggregate or local materials which are cheaper for contractors.

Mitigates Soil Instability and Frost Heaving

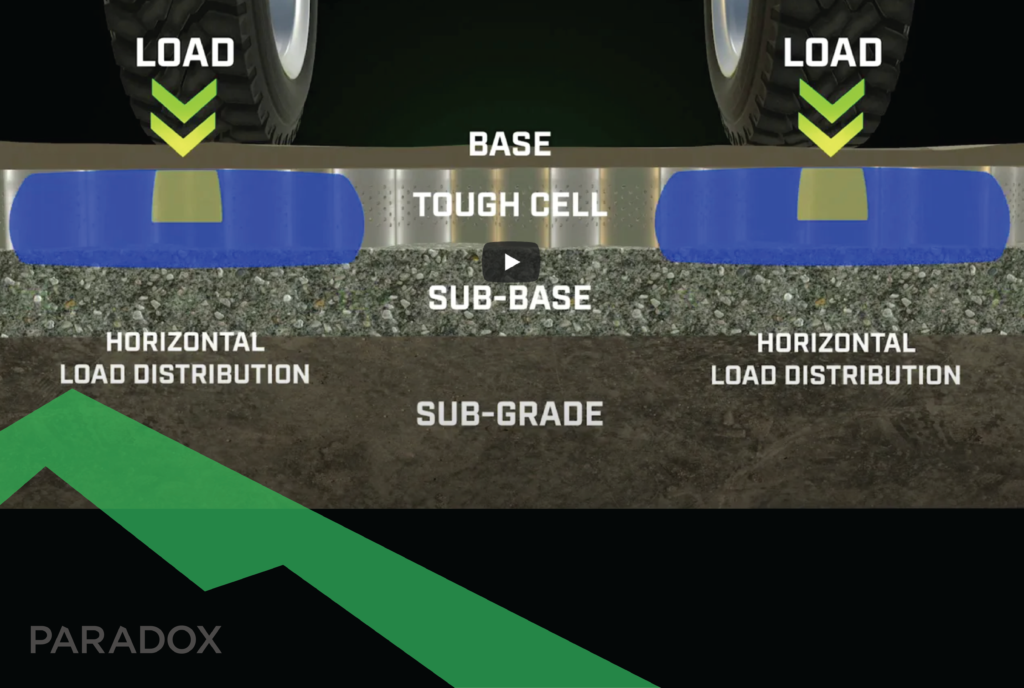

- Freeze-thaw action can lead to soil instability and pavement failures in traditional road construction. Frost heaving can cause surface deformations such as cracks and boils and create a rough riding course. Tough Cell® geocells mitigate these risks by confining the infill material, distributing loads laterally, and thereby reducing vertical stresses on subgrades. This prevents frost-induced expansion and contraction.

Enhances Structural Integrity and Strength

- The confinement structure of Tough Cell® allows the reinforced earthwork structure to maintain its integrity and enables roads to be built and put into operation without 100% compaction. The honeycomb structure of geocells increases the strength and load support capabilities of roads and pads. Made up of perforated cells, it allows drainage and reduces rutting by up to 80%.

- Tough Cell® evenly distributes loads, reducing vertical stress. Its structure increases the subgrade strength and load-bearing capacity of roads, while reducing the required thickness of structural layers.

With its advanced 3D confinement system, Tough Cell® provides robust load support through the “beam effect” even when full compaction isn’t achievable. Its elastic properties reduce subgrade stress during freeze-thaw cycles, minimizing foundational failure risks.

Learn about how Tough Cell® geocells work here:

Tough Cell®: Tailored Solutions for Any Project

Available in multiple strength categories and customizable sizes, Tough Cell® adapts to your project’s specific needs. Paradox’s expert technical team and engineering partner work closely with you to optimize designs for load requirements, soil conditions, environmental challenges, and budget constraints.

Build Smarter This Winter and Beyond

From all-weather roads to slope stabilization and industrial pads, Tough Cell® ensures cost-effective, sustainable, and high-performing foundations. Ready to keep your projects moving come spring?

Contact Paradox at 1.877.MUD.UGLY or email them at [email protected] for more information.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS