In Canada’s dynamic energy sector, maintaining product integrity and compliance with stringent regulatory standards is paramount. A key aspect of this challenge revolves around the precise measurement of liquid color, which serves as a vital indicator of product quality and purity. Recognizing and addressing minute color variations promptly can significantly impact the overall efficiency and sustainability of production processes.

The Challenge of Color Variance in the Energy Sector

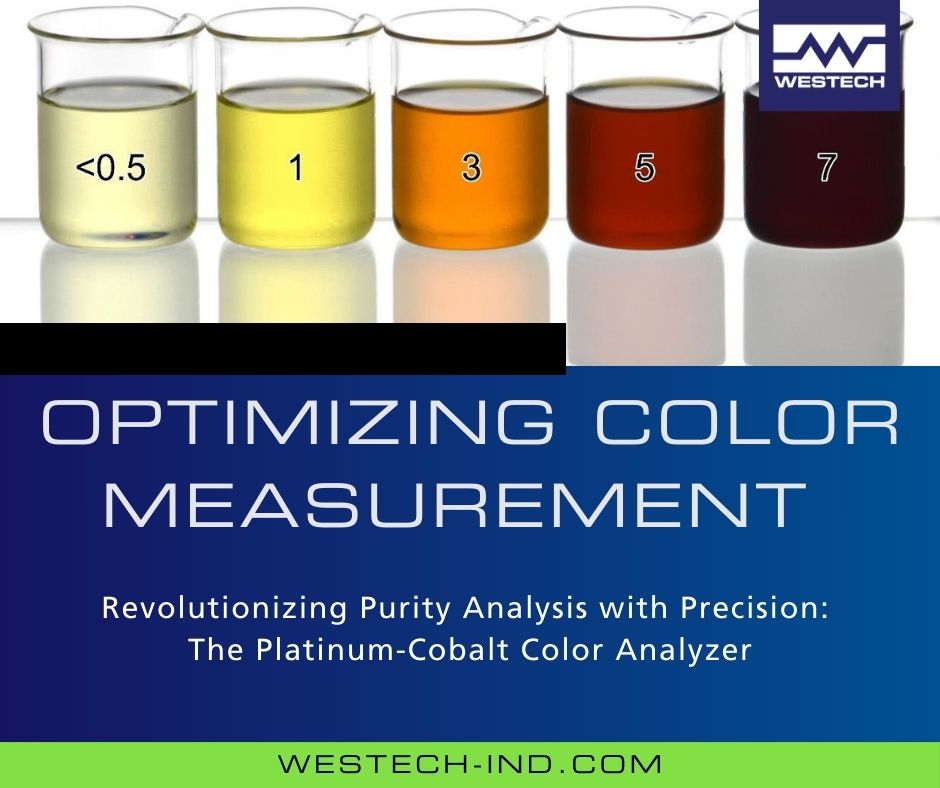

For many chemical compounds utilized within the energy industry—including alcohols, solvents, resins, acids, polymers, and fuels—color indicates more than just aesthetic quality. It reveals crucial information about the state of the product, such as contamination levels and potential degradation due to environmental factors. Traditionally, detecting these subtle changes has been reliant on human observation, which is prone to inconsistencies due to subjective perception and environmental conditions. Moreover, undetected variations can lead to significant product loss, regulatory non-compliance, and potentially hazardous conditions.

The Solution: Advanced Color Measurement Technology

Enter the Kemtrak Platinum-Cobalt (Pt/Co) color analyzer, a cutting-edge solution designed to overcome the limitations of traditional color measurement methods. This analyzer leverages LED-based photometer technology to provide real-time, accurate color assessments directly within the production line. Its dual-wavelength approach not only measures the degree of yellowness—a key indicator of purity and quality—but also compensates for potential interferences like window fouling and suspended particles.

This technology allows for continuous monitoring without the need for frequent recalibration. The analyzer’s robust design and chemically resistant measurement cells ensure reliable operation across a wide range of industrial applications. By automating color measurement, the Kemtrak analyzer minimizes human error, enhances process control, and supports regulatory compliance efforts.

Kemtrak’s Role in Enhancing Industry Standards

Kemtrak’s dedication to innovation is reflected in the design of their Platinum-Cobalt color analyzer, which is specifically tailored to meet the rigorous demands of the energy industry. With a focus on quality control, contamination detection, and adherence to international standards (ASTM D1209, ISO 6271-1, DIN 53409, and BS 5339:76), the analyzer provides a sophisticated yet user-friendly solution that supports sustainable manufacturing practices.

The analyzer’s ability to deliver precise color measurements in real-time aids in early detection of quality issues, thereby reducing waste, preventing costly downtime, and ensuring product consistency. This proactive approach not only saves resources but also contributes to the overall sustainability of the production processes.

The Platinum-Cobalt (Pt/Co) color scale measures the “yellowness” of a liquid and is well suited for quality control and contamination detection

Conclusion: A Partner in Quality and Sustainability

In conclusion, the Kemtrak Platinum-Cobalt color analyzer represents a pivotal advancement in the Canadian energy industry’s quest for precision, efficiency, and environmental stewardship. As the official distributor in Canada, Westech Industrial is proud to offer this innovative solution, helping customers navigate the complexities of product quality and compliance. Through the application of such advanced technologies, Westech Industrial and Kemtrak are setting new standards in the industry, driving towards a future where energy production is not only efficient but also harmonious with our environmental commitments.

To learn more about this innovative product and how it can benefit your operations, please visit Westech Industrial’s website at https://bit.ly/3Wy0b9V or call and speak to one of our technical representatives at 1-800-912-9262.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY Joe Oliver: Fool Me Once, Shame on You. Carney and the Liberals Trying to Fool Me Four Times? Seriously?