4 x 100 Tonne lifting Cylinders with a Split Flow Pump for lifting Pressure Vessels

There are many things you should keep in mind when purchasing Hydraulic Cylinders to ensure you’re getting the best product for your money. In this article, we’re going to the five things we feel are most important.

1. How much does the Cylinder need to lift? Don’t forget a Ton is not a Tonne. While they do indeed sound the same… a ton in 2000 lbs, while Tonne is 1000 kg (2204 lbs). Our Hi-Force Hydraulic Cylinders are manufactured in the UK and rated in Tonnes, however, some other manufacture’s use tons and there is almost a 10% in lifting capacity. Make sure you compare apples to apples when reviewing the specifications.

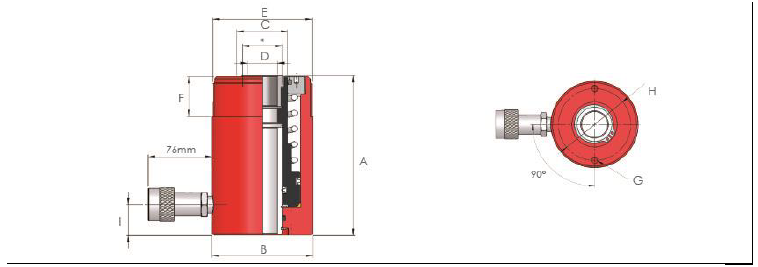

2. What stroke length is needed and are there any size restrictions for placement? At KASI, we have a breakdown of all our cylinder dimensions in metric and standard units, along with dimensioned drawings to make your selection easier. Make sure the cylinder has room to be placed where it’s needed. With blocking, sometimes you can use a slightly shorter stroke, and make multiple lifts.

Detailed Drawing showing dimensions to double-check clearances

3. Do you a need single-acting or double-acting cylinder? Surprisingly the difference between the two is not just the extra port. Single Acting Cylinders are a cost-effective option for simple lifting projects, but if you require both push and pull, or controlled retraction then Double Acting Cylinders are the way to go.

4. Consider the material – steel is strong and durable, while aluminum is lightweight and corrosion-resistant. When determining if you want to use Aluminum Cylinder, you want to ask yourself a question. “Where is the tool going to be used?” In a nice clean machine shop for pushing pins… or is it being loaded onto a service truck that’s heading into a mine. Kasi can help you select the right tool for the job.

5. Does the load need to be held in place once lifted? Seems like a silly question. Not really. The load is often lifted and physically blocked, but Locking Ring Cylinders are sometimes preferred. Locking Rings Cylinders have a mechanical collar which engages and locks the piston in place, meaning that even if hydraulic pressure is lost, the load will not lower unexpectedly. With or without the locking ring KASI has both options available for you.

Do you still have questions?

Feel free to call and speak with one of our technical sales representatives today at 1-855-KASI-CAN or locally at +1-780-440-1749

Summarized by Jason Taylor

KASI Technologies Inc.

www.kasi.ca

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

Borrowing More and More – Federal Budget Brings New Programs and Pains: Margareta Dovgal – Resource Works