CERESIST ceramic lined pup spools increase reliability and outlast traditional weld overlays in erosive and corrosive applications.

A major Alberta oilsands producer was recently looking to improve the reliability and run time of their TSRU’s. Pup spools with various types of weld overlay had been installed downstream of a control valve and were suffering from severe erosion and short life expectancy due to a concentrated jet stream exiting from the control valve. The severe erosion and frequent replacement of the spools had an adverse effect on the overall reliability of the TSRU’s.

Working directly with the end-user, N2X Process Solutions and Ceresist custom-built several 20” ceramic lined spools that were put into service on a trial basis. After several months of run time, the ceramic lined spools were inspected and the results were very positive. The spools were then returned to service. The initial custom design was then modified slightly to improve the spool design and simplify the liner installation. Numerous additional spools have now been procured and are under construction to be placed into service on all of the TSRU’s.

Advantages of choosing Ceresist’s ceramic-lining options are:

- Zero flange leakage: ensuring that the ceramic lining is precisely flush with the flange sealing surface through their AccuGrind process.

- Corrosion resistance: products that they provide have all gone through rigorous testing using aggressive acids and bases at various temperatures.

- Erosion resistance: ceramic materials chosen based on service. However, alumina and silicon carbide ceramics are used most frequently due to their ability to withstand erosion and wear resistance, corrosion resistance, and low long-term cost savings.

Who is Ceresist.

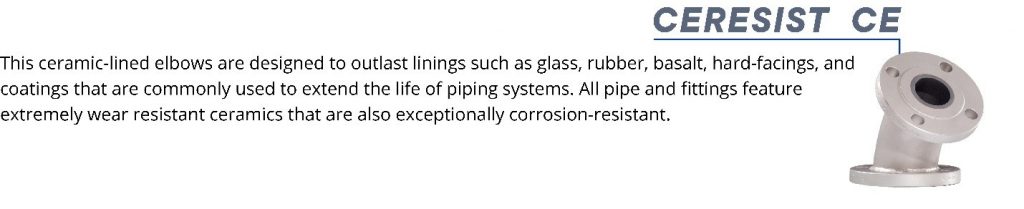

CERESIST was established in 1996 as a ceramic-lined pipe manufacturer. Their piping was initially sold primarily to ceramic valve manufacturers as a complementary product to solve pipe wear downstream of control valves. Since then, Ceresist’s product portfolio has grown to include a wide array of abrasion-resistant process products, with many more in development. They have extensive experience in designing, implementing, and manufacturing ceramic piping, fittings, valves, orifice plates, and ancillary products.

Ceresist’s products are designed with long-term service in mind. Utilizing the finest materials to manufacture their products ensures customers have the longest trouble-free and maintenance-free service life in the industry. They aim to do everything the right way the first time.

CERESIST also believes in long-term, personal relationships with their selected vendors and suppliers, assuring high-quality, consistent raw materials and quick turn-around times; allowing them to provide the highest possible service to their customers.

Who We are.

N2X Process Solutions is a Canadian engineered supplier of market-leading Valve and Actuation Solutions to a wide range of process industries, such as energy, mining, power, and municipal.

We also design and manufacture specialty Surge Relief equipment, used on incompressible fluid pipelines, primarily in the midstream Oil and Gas Industry.

At N2X Process Solutions, we provide ourselves on being a responsible company for our community and for our clients. We are committed to providing exceptional customer service and ensuring the safety and reliability of our clients’ operations.

Click Here to find out more and Contact Us for further inquiries.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY Joe Oliver: Fool Me Once, Shame on You. Carney and the Liberals Trying to Fool Me Four Times? Seriously?