When it comes to emission reduction, enclosed vapour combustors, also known as EVCs, or simply combustors, are gaining ground as an emerging technology. Combustors were developed to eliminate methane emissions from sources including casing gas venting, tank venting, pneumatic vent discharge and others. Aside from an EVC’s higher combustion efficiency, one of the main benefits of a combustor / EVC over a typical flare is that combustors meet specific safety requirements that allow them to be spaced as close as 10 meters from the wellhead or any other flammable vent source.

One of the specific safety requirements that a combustor needs to meet for the 10 meter spacing requirement is backflash protection. Backflash, or flashback, protection is required for the piping that connects the emission source to the combustor as well as for the air intake used by the EVC for combustion.

SOURCE LINE BACKFLASH PROTECTION

For the piping that connects the emission source (tanks, pneumatic devices, compressor seals, casing gas, etc.), an inline deflagration arrestor is typically used. Inline deflagration arrestors prevent the propagation of flame through the device by quenching the flame. One common style of deflagration arrestor, seen below, uses crimped metal ribbons to accomplish this.

This type of deflagration arrestor is frequently used for source line backflash protection by combustor manufacturers and is well suited for this purpose due to the higher pressure requirements and closed environment (pipe). Emission Rx, for example, uses BelGASFM arrestors on their combustors to protect against source line backflash. “Like Emission Rx, BelGAS Flame Management has in-house manufacturing and design. That increases accountability, resulting in a high quality product” – Jeff Nelson, Emission Rx President.

AIR INTAKE BACKFLASH PROTECTION

Air intakes of combustion devices and combustible gas vents, use multiple methods of backflash protection that meet the safety requirements implemented by provincial, state and federal regulations as well as industry standards.

Flame arresting devices are a type of backflash protection that have been used in multiple commercial and industrial applications for many years. Applications that even include items such as engine exhaust pipes and commercial hot water heaters. Regardless of the design, they all operate with the same goal of removing heat from a flame by forcing the flame to travel through narrow passages. Some types of flame arresting devices are crimped ribbon, metal foam and wire flame screens.

Aside from a physical flame arresting device, there are also other backflash protection methods that exist. One alternative method is to use velocity to stop the advancement of flame.

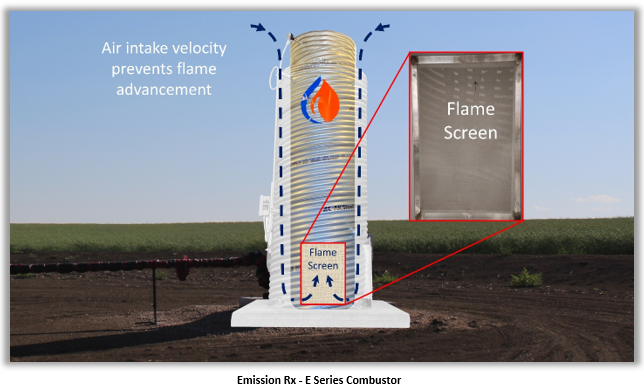

Emission Rx, as a trusted combustor manufacturer, has actually chosen to use two methods of backflash protection on their E-Series enclosed combustors. In addition to using an accepted wire flame screen on the inside of the combustor, the double hull design of the E-series also uses air velocity to stop flame advancement.

“At Emission Rx, we take a lot of pride in our backflash protection design” says Justin Bouchard, Emission Rx Design Engineer. “We use a unique approach that includes multiple levels of protection installed within the combustor.”

APPROPRIATE SIZE AND LOCATION

Some combustor manufacturers mount their air intake flame arresting devices on the outside of the combustor. Doing this can make the arrestor susceptible to many environmental forces that could restrict air flow and ultimately impact performance and effectiveness. It is important to ensure that any flame arresting device is sized appropriately for its purpose and, if the external arresting device is located close to the ground, that it is kept free and unencumbered from ice, snow, dirt, dust, water, etc.

“Restricted air flow could cause a reduction in combustion efficiency, or worse, cause unintended non-arrested air to find its way into the combustion chamber” says Bouchard. “An added benefit of using internal air arresting devices on our E-Series combustors is that they aren’t subject to external blockages like hoar frost or snow build up.”

Enclosed combustors are advancing the level of safety and performance in the energy industry. With safety requirements written into the regulations, producers are finding that enclosed combustors are an easy way to safely & reliably manage waste gases and eliminate methane venting from their sites.

“EnviroVault and Emission Rx are companies that have always focused on operator safety, environmental stewardship and regulatory acceptance. The E-Series enclosed combustor is no exception to this.”

ERx combustors are distributed solely by EnviroVault LP. For more information visit www.envirovault.com

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Canadians Should Decide What to do With Their Money – Not Politicians and Bureaucrats