SLMS is a Response to a Formal Review of Alberta Pipeline Safety

In 2013, Alberta’s Minister of Energy directed the AER to conduct a third-party pipeline safety review. The focus was on the adequacy of pipeline requirements and industry best practices, response to pipeline incidents, pipeline integrity management, and the safety of pipelines at or near water crossings.

A key finding of the Review was a recognition that 20-years of prescriptive regulations and time-based directives have proven inadequate to create the desired level of pipeline performance, and that more must be done by both the Operator and Regulator to ensure public safety.

In response, the AER mandated the adoption of Safety and Loss Management Systems (SLMS) as an assurance that risk management, and maintenance performed onto pipeline infrastructures will improve pipeline performance.

Adoption of SLMS drastically changes the regulatory philosophy for pipeline safety and reliability by moving away from onerous prescriptive regulations. This shifts the accountability of identifying and mitigating safety and reliability risks away from the government and onto pipeline operators.

“Without changing our patterns of thought, we will not be able to solve the problems that we created with our current patterns of thought.”

~ Albert Einstein

SLMS – Definition of CSA-Z662 Compliance

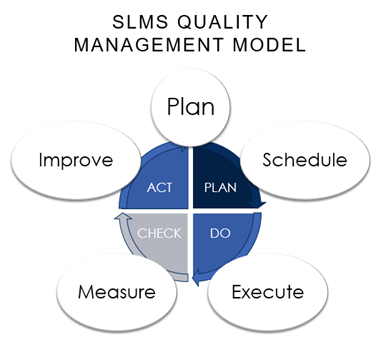

A Safety and Loss Management System (SLMS) is a quality management system designed to ensure an organization is meeting requirements and continuously improving its processes. Global adoption of SLMS programs by major industries since the 1970’s has proven safety management programs can reduce the financial exposure and damage to the reputation of an organization by reducing accidents.

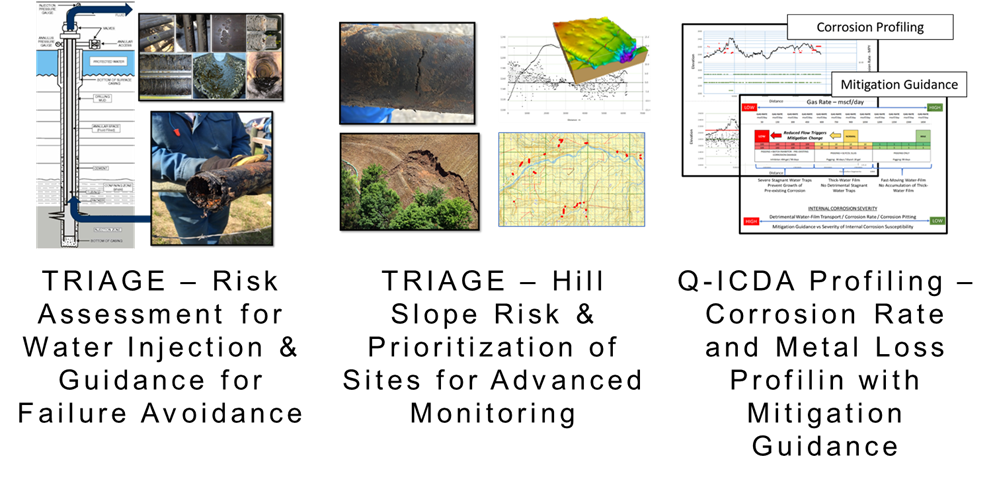

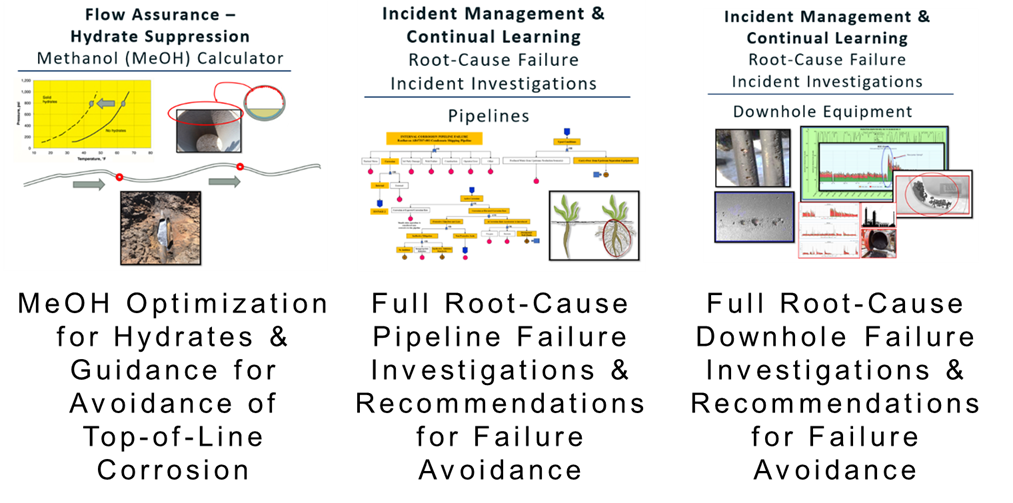

SLMS is an “owner-user” approach to pipeline integrity management & compliance. The foundation of a successful SLMS is adoption of advanced hazard classification models that fully characterize all potential integrity hazards, and which consider and communicate the implication of changing conditions to corporate risk exposure.

- SLMS programs focus on:

- o risk-optimization of mitigation, inspection, and monitoring; and,

- o continual learning by promoting goal setting, planning, measuring, and improving performance.

The scope of the organization’s operations and therefore its risk profile determine how the SLMS is structured and what resources are required to manage risk effectively.

Quality management fails when you delegate it. So, when I say commitment, I mean CEOs must be actively working and doing things, not just saying, “Yes, I bless this thing, and here’s some money to do it.”

~ Philip Crosby, Quality Management Pioneer

SLMS within CSA – Z662 – 2019 Oil & Gas Pipeline Systems

CSA-Z662-2019 specifies a Safety and Loss Management System (SLMS) and Integrity Management Program (IMP) be in place with the expectation operators will be better able to anticipate integrity hazards, analyze, assess, and manage risks that can adversely affect safety and the environment.

- Updates to the requirements of SLMS and IMP programs are included as CSA-Z662-2019 / Annex A and Annex N, respectively;

- CSA-Z662 / Annex N were made mandatory within Alberta Pipeline Rules – Section 9.0 in 2011 & Annex A in 2015.

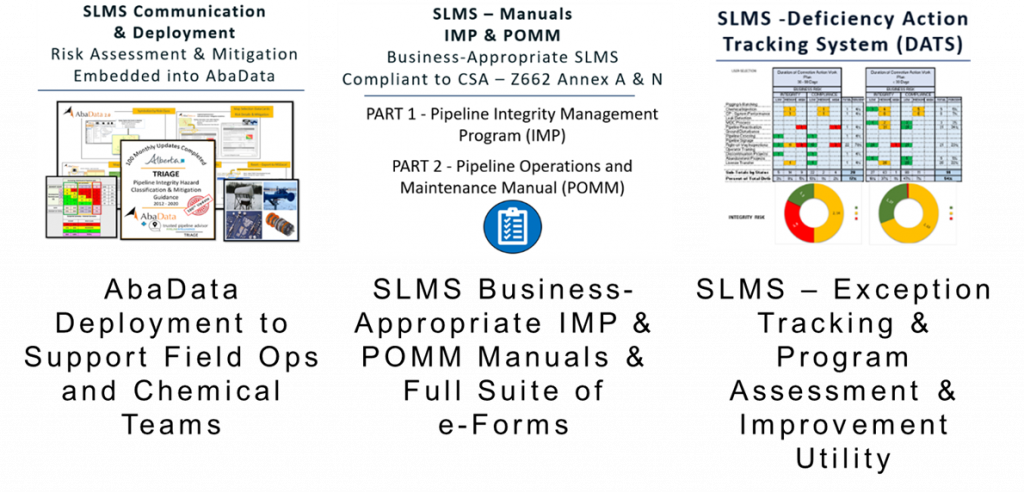

Industry SLMS – IMP Audits – Summary of Key Findings

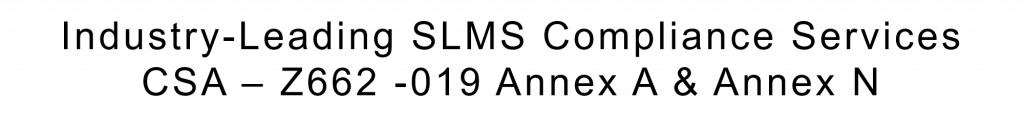

A summary of Regulatory SLMS Audits suggests operators need to make further efforts to formalize their management review process, develop and implement internal audits to assess the effectiveness of their SLMS program and update their IMP on a regular basis. Specific weaknesses have been identified and reported:

- evaluation of integrity maintenance and mitigation activities;

- performance measurement, analysis of data and identification of improvement opportunities;

- tracking & reporting of non-compliance & corrective action activities;

- tracking and trending of key performance indicators (KPIs);

- identification and analysis of all potential hazards on an ongoing basis;

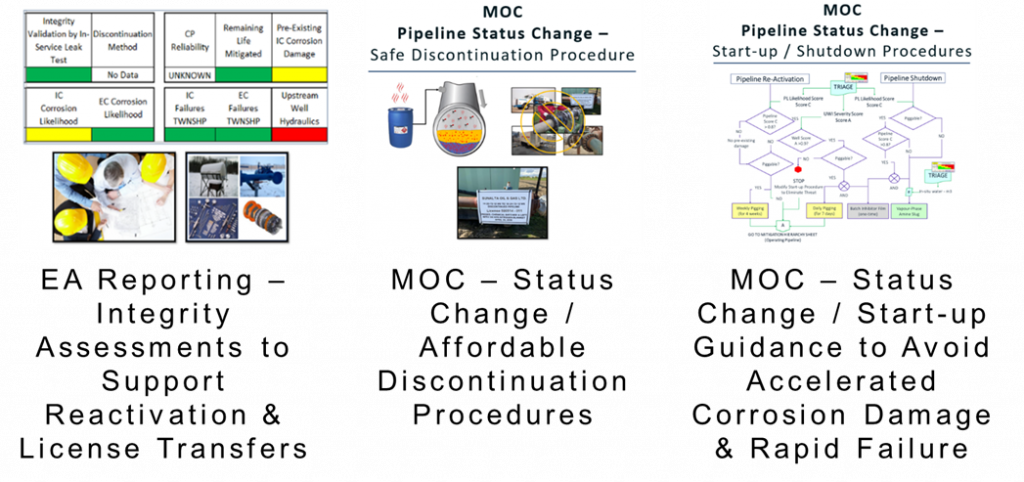

- management of change (MOC);

- reassessment of risk upon operational changes and incidents

- risk mitigation of non-piggable pipelines;

- management of dead-legs; and,

- tracking and identifying gaps within operating training and competency versus critical tasks associated with maintaining reliable pipeline integrity.

“Overcoming the risk-blindness caused by years of time-based regulations is the greatest barrier to achieving the desired level of pipeline safety.”

~ Trusted Pipeline Advisor

Supporting the transition to quality SLMS – Pipeline Integrity Management

David Richardson, P.Eng.

(403) 880-2835

david@trustedpipelineadvisor.com

https://www.trustedpipelineadvisor.com

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

China’s Transition Hampered by Flat-Lining Energy Intensity