Jim Boucher, former chief of the Fort McKay First Nation, will help raise profile of Acceleware | Kisâstwêw as company works toward commercialization

The translation of “heat” in Cree is “Kisâstwêw,” and that’s half of the name of a new Indigenous business partnership working to advance technology that could, if proven and commercially deployed, dramatically reduce oil sands water use and greenhouse gas emissions by changing how heat and steam are used.

Since 2010, Calgary-based Acceleware has been progressing its radio-frequency recovery technology, called RF XL, toward field testing. This October the company received regulatory approval to proceed, and a month later announced the backing of influential Indigenous leader Jim Boucher through the creation of Acceleware | Kisâstwêw.

“I think everybody in the Canadian oil sector is working towards improving their environmental record. This technology is one avenue with respect to achieving good, productive, clean oil production, with minimal damage to the land and the environment,” says Boucher, who served as chief of the Fort McKay First Nation for more than 30 years between 1986 and 2019 and has been recognized for “remarkable accomplishments” in business and community leadership.

In 2020, Boucher launched Saa Dene Group of Companies, which in addition to Acceleware | Kisâstwêw has a portfolio of partnerships ranging from K-12 education and online health care to manufacturing, construction and well servicing.

Boucher says Saa Dene approached Acceleware earlier this year because he has taken an interest in improving the efficiency of heavy oil recovery technology. Under the partnership, Saa Dene will help to raise the profile of the company’s technology with oil sands producers, communities and policy makers, and help raise funding for commercial-scale development.

“We were looking for ways to increase our engagement with Indigenous communities, so it was perfect timing,” says Acceleware vice-president Mike Tourigny.

“The opportunity to have some of Jim Boucher’s experience and his reputation as a champion in responsible and sustainable development, having him join us as a supporter we think will open doors and really help us accelerate our commercialization.”

How RF XL works

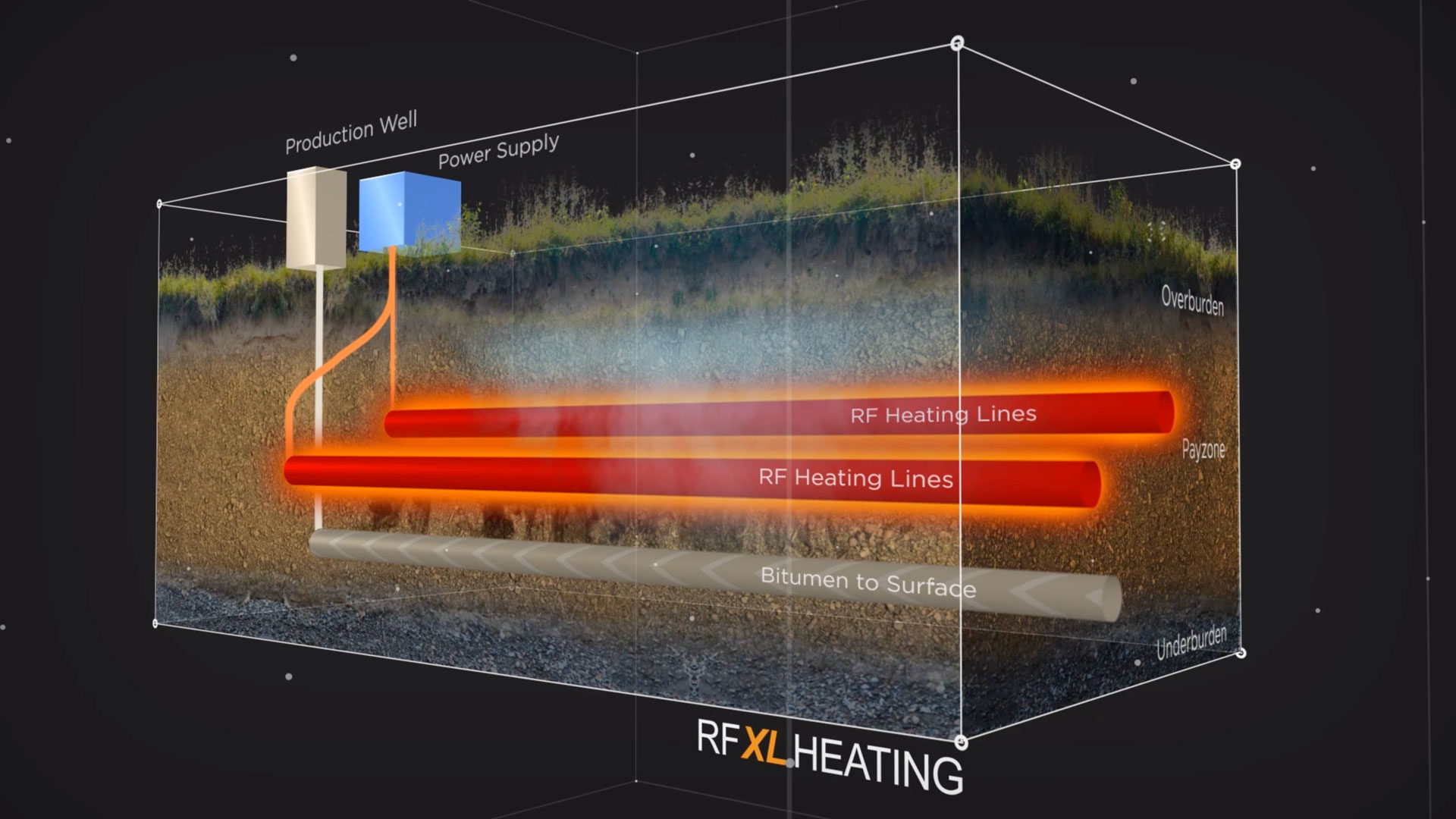

Tourigny describes that in Acceleware’s RF XL technology, electricity is converted to electromagnetic energy at the surface and is then delivered to the oil pay zone through radio-frequency heating lines.

That energy seeks out naturally-occurring water molecules from within the oil-bearing formation and heats them to create a steam chamber.

Like in conventional SAGD, the steam chamber heat mobilizes the bitumen, and via gravity the mobilized bitumen flows to a production well at the bottom of the reservoir.

The difference is that the steam chamber is created inside the reservoir instead of by burning natural gas to heat water on the surface, which eliminates fresh water use and could reduce GHGs to as low as zero, depending on the source of electrical generation.

Not requiring water processing or steam generation facilities is also expected to reduce capital and operating costs by at least 40 per cent, Tourigny says.

Development of the technology is funded in part by $10.25 million from Sustainable Development Technology Canada and Emissions Reduction Alberta.

Pilot Test

In October 2020, Acceleware received regulatory approval to proceed with a field trial at a site in the Cold Lake oil sands region owned by Broadview Energy.

Tourigny says construction is expected to start in December, followed by startup as early as March. The agreement with SDTC and ERA is for an initial heating phase for approximately six months.

“We may choose to extend that if it’s going well and we want to continue to learn what happens,” Tourigny says, adding that the company has already done extensive testing and accomplished milestones it considers encouraging.

“We’ve done a 1/20th scale test near the surface with the entire system that was successful, [and] we’ve demonstrated that the converter works at the efficiency and power levels that we need it to, so we’re really confident about those components already,” he says.

“Getting it in the ground, showing that we can drill and complete the well and then heat and produce oil will be an act of validation. Fundamentally, if we’re running for a number of months and heating, that’s going to be one of the biggest points of proof that we are hoping to accomplish here.”

Commercialization

Tourigny believes that once RF XL technology is proven in the field it could be adopted relatively quickly by smaller-scale producers in the area of the pilot test.

It would take more time for the larger oil sands players to validate the results for larger-scale operations, but “we would hope to see several of them jumping with pilots in the oil sands as well,” he says.

The addition of Boucher’s support through Acceleware | Kisâstwêw is expected to help raise awareness about the benefits of alternate methods of extraction that can be applied to heavy oil production.

In 2018, the Energy Council of Canada named Boucher the 2018 Canadian Energy Person of the Year, noting his work as board chairman of the Fort McKay Group of Companies, which has developed and sustained decades of successful oil sands business ventures for Fort McKay members.

The council also highlighted Boucher’s work as a driving force behind Fort McKay and Mikisew Cree First Nation’s November 2017 purchase of 49 per cent interest in Suncor Energy’s East Tank Farm. The $545-million deal is one of the largest business investments to date by a First Nations entity in Canada.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Canadians Should Decide What to do With Their Money – Not Politicians and Bureaucrats