STEP is pumping more hours per day than almost any other fracturing service provider in North America. And when time is money, seconds matter.

Efficiency is a driving force of STEP’s business strategy and a building block of the Exceptional Client Experience. As we continue to make growth a priority, finding efficiencies in our operations remains top-of mind.

One of the ways STEP improves efficiencies in fracturing services is by managing maintenance schedules which increases available pumping hours per day. By deliberately focusing on one goal, collaborating with clients, and engaging our onsite professionals, STEP has achieved pumping efficiencies that were unattainable in the past. HSE incidents have also decreased which is indicative of strong employee engagement. This continuous improvement is as a result of consistent STEP-client partnerships which is required to create momentum in any operation.

So how is this done? By collaborating, holding each other accountable and focusing on one strategic goal; increasing pumping hours.

- STEP takes a collaborative approach within our own organization, across all departments and creates a cadence of accountability that allows us to focus on finding efficiencies and increasing pumping hours for our clients. It’s from these collaborative conversations and a multidisciplinary approach that new ideas have emerged and resulted in real wins.

- STEP is committed to partnering with operators and does so with regular bi-weekly meetings and pre/post-pad reviews.

- STEP delivers accurate data through its STEP-Link data management tool. Clients can securely log-in and view their fracturing post-job data with the push of a button. With total transparency, clients know what is happening in their operations, and where improvements can be made.

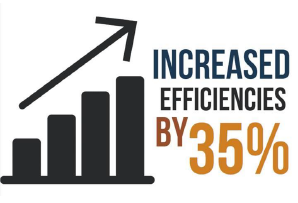

Client A

- Efficiencies

- Average pumping hours per day in Q4 2018 over three pads – 14.03

- Average pad pumping hours per day during most recently completed 4 well pad – 18.93

- Safety

- 2019 – increase in man-hours by over 65%

- 40% fewer injuries, no recordable incidents

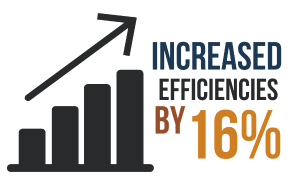

Client B

- Efficiencies

- Average pumping hours per day on one pad in February 2019 – 15.47

- Average pumping hours per day on one pad in August 2019 – 17.95

- Safety

- 2019 – increase in man-hours by over 18%

- No recordable incidents

In both cases STEP saw an increase in man-hours, but a decrease in incidents. This is indicative of an engaged/focused workforce and creates a safer working environment.

Conclusion:

By increasing pump time, operators are able to get their wells producing faster and significantly improve project economics.

Learn more about STEP Energy Services: www.stepenergyservices.com

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

COMMENTARY: Canadians Should Decide What to do With Their Money – Not Politicians and Bureaucrats