Author: Max Cook

One of the key challenges maintenance managers face is predicting how much maintenance will be needed in the coming year. The amount of work has a direct impact on the number of workers needed to carry out each job, in turn having a direct impact on the maintenance budget. Too often, maintenance budgets are based on a combination of historical experience and a high degree of individual judgement on the part of the manager. Consequently, they tend to be far too optimistic and are frequently overrun, causing headaches for managers and resource bottlenecks when demand has been underestimated.

Predictive Analytics (PA) models have been designed to address exactly this issue. Using both future and historical data, mathematical models analyze relationships to create accurate resource forecasts based on possible scenarios. This allows managers to make clear decisions about how much money and human capital they will need to maintain their plants according different degrees of site utilization. This article looks at two key areas where Predictive Analytics provides valuable maintenance solutions.

Budget Forecasting

The following six factors have a strong influence on the maintenance budget:

- Scope, structure and wear of equipment

- Load and pressure limit of equipment

- Investment strategy (new and additional investment)

- Technological advances

- Leadership and organization of maintenance

- Price and quality of partner companies.

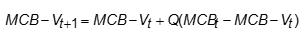

Data regarding all of the above factors is collected and entered into the PA model, which calculates trends, correlations and regressions via a mathematical technique called “exponential smoothing.” This uses weighted averages of past observations which decrease in value exponentially the further into the past a value goes. The more recent the observation, the higher the weight attributed to it. This mathematical approach allows conditional probabilities of future performance to be created based on statistical relationships, and has the advantage of predicting likely demand across boundaries (such as countries) in a relatively simple, effortless way. Managers can then use these demand values to create an accurate maintenance budget.

MCB-Vt+1 = Demand (Predicted value) for timeframe t+1

MCB-Vt = Demand (predicted value) for timeframe t

Q = Smoothing constant

MCBt = Actual consumption in timeframe

Human Resource Requirements

Let’s assume that a manager has to outsource 98% of a site’s maintenance requirements to a contractor. How can the organization be structured so that the necessary in-house planning and scheduling skills are not lost?

In a manner similar to the calculation of maintenance budgets, PA models can also be used to forecast staff requirements according to different indicators. This is most helpful when considering the roles of planner and scheduler as they, by nature, require an estimation of future human resource demand and have a direct impact on safety, site availability and productivity.

The model works by separating maintenance jobs into preventive, predictive or corrective categories, and then again into small, medium or large orders. This enables necessary work to be organized into two groups: those with high priority (needing urgent attention) and those with low priority (plannable). Data from an entire year concerning production times (shift times, weekends) is then entered and used to predict the workdays on which maintenance should be coordinated and corrected. The average planning requirements per job type are then calculated in working hours, as well as how many contractors will be needed per year to supplement in-house teams according to selected levels of site utilization.

In the graph below, the number of planners and schedulers required is predicted according to different given percentages of site utilization: 50%, 75% and 95%. Managers can obviously chose their own specific level of utilization – in this case, “chosen probability” – and receive an accurate forecast of the number of resources needed to achieve that.

Joint Venture

Too often, decisions concerning questions of human resource and budget planning such as these are made based on an individual manager’s instinct and past experience. While historical experience is certainly an important factor, basing decisions about the future only on one person’s know-how means that the results will be subjective and are unlikely to be accurate. Indeed, according to Israeli-American psychologist and Nobel Prize winner Daniel Kahnemann, predictions concerning the amount of time needed to complete a future task tend to fall prey to “optimism bias,” where people tend to underestimate the likelihood of a future negative outcome regardless of their experience that past tasks have taken longer than expected. This phenomenon is known as “planning fallacy” and often results in time and cost overruns. While personal experience should not be ignored, there are obvious advantages to using Predictive Analytics models to reduce that bias. Ultimately, the most pragmatic approach is a combination of both: a joint venture into the future of accurate budget and resource forecasting.

Share This:

CDN NEWS |

CDN NEWS |  US NEWS

US NEWS

Canadians Should Decide What to do With Their Money – Not Politicians and Bureaucrats